Welcome to the world of injection molding, where precision, innovation, and efficiency intersect to create a myriad of products that shape our lives. In this blog, we embark on a journey to delve into the diverse universe of injection molding machines. From hydraulic to electric, and everything in between, we’ll explore the different types of machines that power the manufacturing landscape.

The Basics of Injection Molding Machines

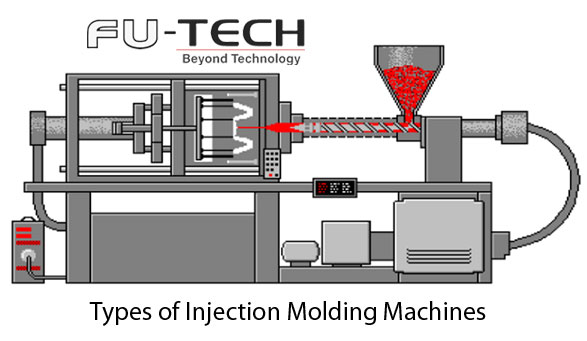

Before we dive into the specifics, let’s lay the foundation. Injection molding machines are the workhorses of the manufacturing process. They transform raw materials into intricate parts by injecting molten material into a mold, allowing it to cool and solidify before being ejected. The choice of injection molding machine can significantly impact the final product’s quality, efficiency, and production cost.

Hydraulic Injection Molding Machines

Power and Versatility: Hydraulic machines have been a cornerstone of injection molding for decades. They rely on hydraulic power to drive the molding process, making them capable of handling a wide range of materials and applications.

Cost-Effective for Large Parts: Hydraulic machines are particularly advantageous when producing large and heavy parts due to their high clamping force capabilities.

Considerations: While hydraulic machines are versatile, they can be less energy-efficient compared to their electric counterparts and may require more maintenance.

Electric Injection Molding Machines

Precision and Energy Efficiency: Electric machines have gained prominence for their high precision and energy efficiency. They utilize electric motors to drive the process, resulting in reduced energy consumption and more precise control over the molding cycle.

Clean and Quiet: Electric machines generate less noise and produce fewer emissions compared to hydraulic machines, making them a favorable choice for cleanroom environments.

Initial Investment: Electric machines often come with a higher upfront cost, but their long-term operational savings can outweigh the initial investment.

Hybrid Injection Molding Machines

The Best of Both Worlds: Hybrid machines combine the strengths of hydraulic and electric machines. They use electric servo motors for the injection process while relying on hydraulic power for clamping and ejection.

Energy Savings: Hybrid machines offer energy efficiency without compromising on clamping force, making them an attractive option for manufacturers seeking a balance between performance and economy.

Advanced Control: The integration of both hydraulic and electric systems requires sophisticated control technology to optimize performance.

Two-Platen Injection Molding Machines

Space and Flexibility: Two-platen machines feature a unique design with two platens that move horizontally. This design offers ample space for large molds and complex parts.

Reduced Deflection: The two-platen design minimizes platen deflection, resulting in improved part quality and consistency.

Versatility: Two-platen machines are versatile and can accommodate a wide range of molds and part sizes.