Blow Injection Molding Machine Manufacturer in Jharkhand - Fu-tech

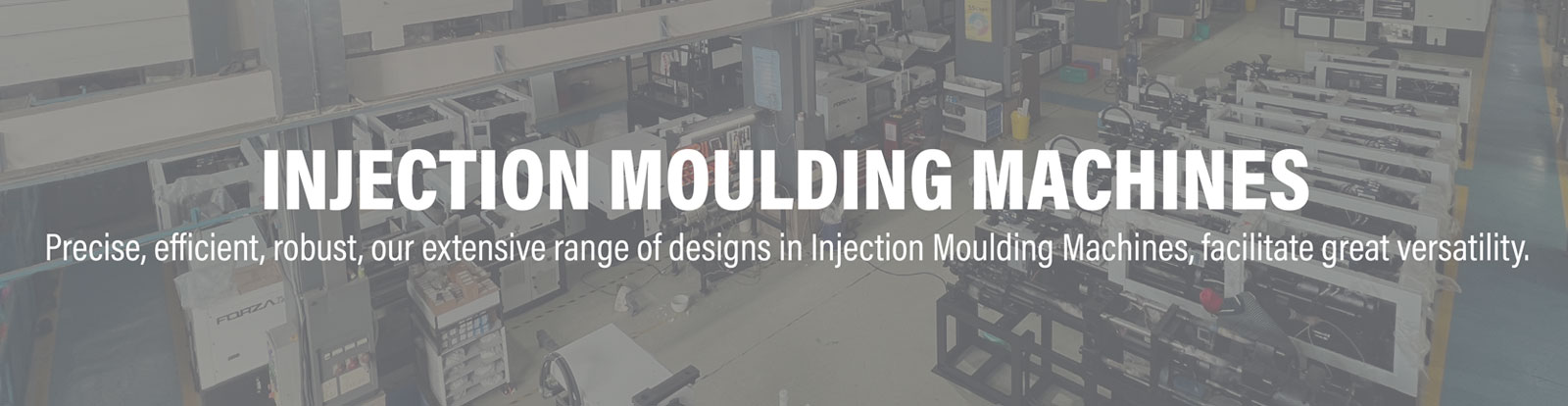

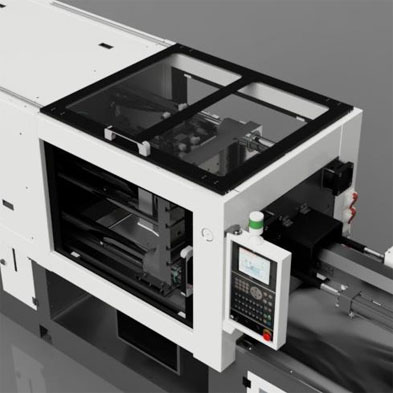

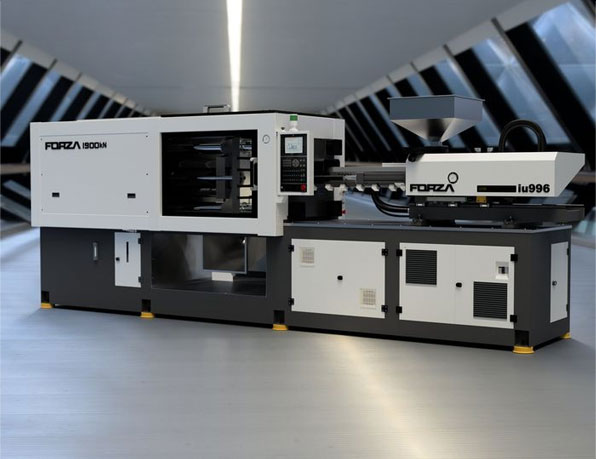

At Fu-tech Machinery, we specialize in delivering high-quality blow injection molding machines tailored to meet the diverse needs of our clients across India. Whether you're looking for precision, efficiency, or reliability, our machines are designed to exceed your expectations.

As a trusted supplier in Jharkhand, we prioritize delivering superior products that offer unmatched performance and durability. With our state-of-the-art manufacturing facilities and experienced team, we ensure that each machine meets the highest standards of quality and craftsmanship.

Partner with Fu-tech Machinery for all your blow injection molding needs and experience the difference firsthand. We take pride in our ability to provide innovative solutions that drive success for our customers. Contact us today to learn more about our products and services.

Applications of Blow Injection Moulding Machines

Blow injection molding machines are versatile tools with a wide range of applications across various industries. Here are some key applications:

- Packaging Industry: Blow injection molding machines are extensively used for producing packaging materials such as bottles, containers, and jars. These machines offer fast production speeds and precise molding capabilities, making them ideal for manufacturing a variety of packaging solutions.

- Automotive Sector: In the automotive industry, blow injection molding machines are utilized for producing components like automotive fuel tanks, air ducts, and reservoirs. These machines enable manufacturers to create lightweight and durable parts with complex shapes, meeting the stringent requirements of the automotive sector.

- Medical Devices: Blow injection molding machines play a crucial role in the production of medical devices and equipment such as bottles for pharmaceuticals, containers for medical supplies, and components for medical devices. The machines ensure the production of sterile and high-quality medical products that comply with industry regulations.

- Consumer Goods: From household products like detergent bottles and shampoo containers to industrial items like drums and storage tanks, blow injection molding machines are widely used in the manufacturing of consumer goods. The versatility of these machines allows for the production of customized products to meet consumer preferences.

- Cosmetics Industry: Blow injection molding machines are employed in the cosmetics industry for manufacturing containers and packaging for various beauty and personal care products. The machines offer precise control over design and dimensions, allowing for the creation of aesthetically appealing packaging solutions.

Key Features of Blow Injection Moulding Machine

Here are some key features of blow injection molding machines:

Versatility

Our blow injection molding machines are versatile and adaptable, capable of producing a wide range of products with varying shapes, sizes, and complexities.

Precision Control

With advanced control systems, our machines offer precise control over parameters such as temperature, pressure, and speed, ensuring consistent and high-quality output.

Efficiency

Designed for efficiency, our machines optimize material usage and minimize cycle times, resulting in increased productivity and cost-effectiveness.

Durability

Built to withstand rigorous industrial environments, our machines are constructed from high-quality materials and components, ensuring long-term reliability and performance.

User-Friendly Interface

Featuring intuitive interfaces and easy-to-use controls, our machines are designed for user convenience, making operation and maintenance hassle-free.

Customization Options:

We offer customizable features and configurations to suit specific production requirements, allowing our customers to tailor the machine to their unique needs.

Advantages of Blow Injection Moulding Machine

Blow injection molding machines offer several advantages over traditional molding methods:

- Versatility: These machines are capable of producing a wide range of products, from simple containers to complex shapes, allowing for versatile manufacturing options.

- Cost-effective: With their ability to produce hollow parts with less material, blow injection molding machines can significantly reduce material costs compared to solid molding techniques.

- Efficiency: The automated process of blow injection molding ensures high production rates and consistent quality, leading to increased efficiency in manufacturing operations.

- Lightweight Products: As blow injection molding creates hollow parts, it results in lightweight products, which can be advantageous in various industries such as packaging and automotive, where weight reduction is crucial.

- Design Flexibility: These machines allow for intricate designs and features to be incorporated into the final product, offering design flexibility that meets specific customer requirements.

- Uniform Wall Thickness: Blow injection molding ensures uniform wall thickness throughout the product, leading to enhanced strength and durability, as well as consistent performance.

- Reduced Waste: The ability to use less material and create hollow parts minimizes waste generation, making blow injection molding a more environmentally friendly manufacturing process.

FAQ'S To Blow Injection Molding Machine Manufacturer in Jharkhand

-

What is a blow injection molding machine?A blow injection molding machine is a specialized equipment used in the manufacturing process to produce hollow plastic products. It works by injecting molten material into a mold cavity, where it is then inflated to form the desired shape.

-

What types of products can be produced with blow injection molding machines?Blow injection molding machines are versatile and can be used to produce a wide range of products, including bottles, containers, automotive components, and consumer goods.

-

What are the advantages of choosing a blow injection molding machine?Blow injection molding offers several advantages, including high production efficiency, precise control over product dimensions, reduced material wastage, and the ability to create complex shapes with ease.

-

How can I choose the right blow injection molding machine for my needs?When selecting a blow injection molding machine, consider factors such as production volume, desired product specifications, material compatibility, energy efficiency, and after-sales support. Consulting with a reputable manufacturer can help you make an informed decision.

-

Do you provide customization options for blow injection molding machines?Yes, we understand that every client has unique requirements. That's why we offer customization options to tailor our machines according to specific preferences, such as mold design, production capacity, and automation features.