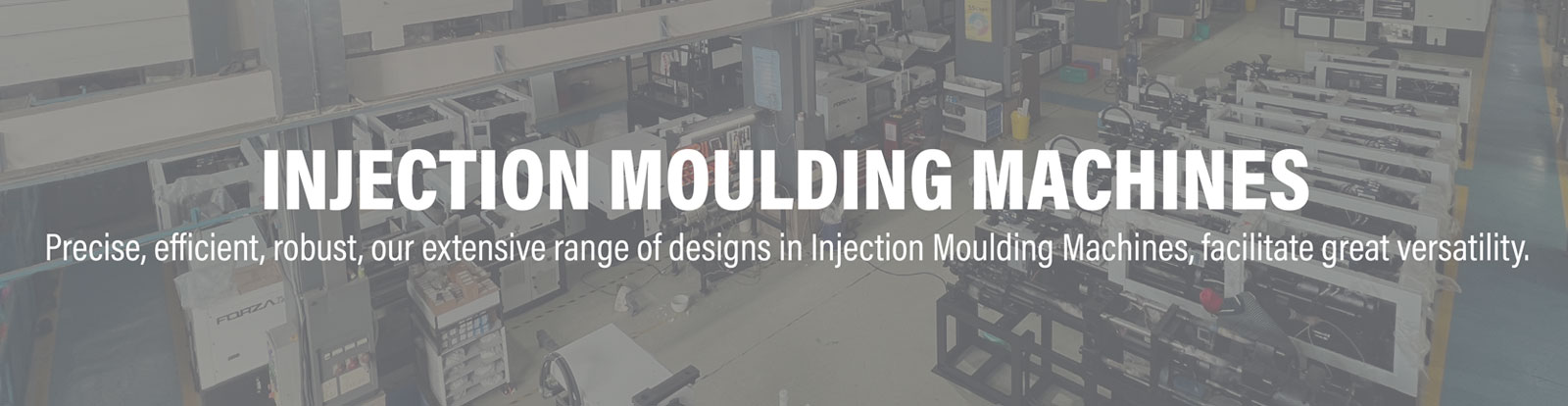

Servo Injection Molding Machine Manufacturer in Jharkhand - Fu-tech

At Fu-tech Machinery, we understand the importance of precision and efficiency in every manufacturing process. That's why our servo injection molding machines are engineered with cutting-edge technology to deliver unparalleled performance and reliability. Whether you're in automotive, packaging, electronics, or any other industry, our machines are designed to optimize productivity while minimizing energy consumption.

As a trusted servo injection molding machine manufacturer in Jharkhand, we prioritize customer satisfaction above all else. Our dedicated team of experts works closely with clients to understand their specific requirements and provide customized solutions that exceed expectations. From initial consultation to after-sales support, we are committed to ensuring a seamless experience for every customer.

Applications of Servo Injection Moulding Machines

Servo injection molding machines offer versatile applications across various industries due to their advanced technology and precision control. Here are some key applications where servo injection molding machines excel:

- Automotive Components: Servo injection molding machines are widely used in the automotive industry for manufacturing precision components such as interior panels, dashboards, bumpers, and exterior trims. The high accuracy and repeatability of servo-driven systems ensure consistency in part quality, meeting the stringent standards of the automotive sector.

- Packaging: In the packaging industry, where speed and accuracy are crucial, servo injection molding machines play a vital role. These machines are capable of producing thin-walled packaging containers, caps, closures, and other packaging components with fast cycle times and minimal material wastage, making them ideal for high-volume production.

- Electronics: Servo injection molding machines are employed in the electronics industry for manufacturing intricate components such as connectors, housings, and casings for electronic devices. The precise control offered by servo systems ensures the production of parts with tight tolerances, essential for electronic applications.

- Medical Devices: With the growing demand for precision and cleanliness in medical device manufacturing, servo injection molding machines are preferred for producing components such as syringe barrels, IV connectors, and surgical instruments. The cleanroom compatibility and accuracy of servo-driven systems make them well-suited for medical applications.

- Consumer Goods: From household appliances to consumer electronics, servo injection molding machines are utilized for producing a wide range of consumer goods. These machines enable the production of complex shapes, intricate designs, and aesthetically appealing parts with high repeatability, meeting the diverse demands of the consumer market.

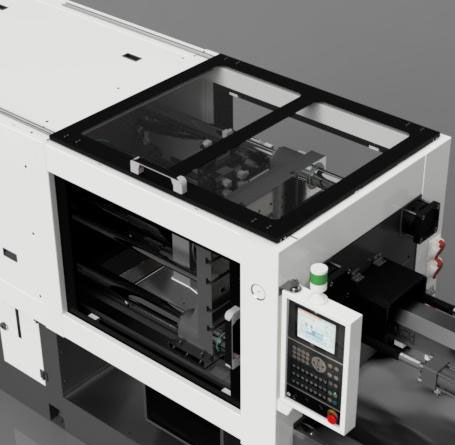

Key Features of Servo Injection Moulding Machine

Toggle Injection Molding Machines offer several key features that make them indispensable in the manufacturing industry:

Energy Efficiency

Servo injection molding machines save energy with precision-controlled servo motors.

Fast Response Time

Servo motors respond quickly to changes in commands, enabling faster cycle times and increased productivity.

Quiet Operation

Servo motors operate more quietly compared to hydraulic systems, creating a quieter working environment.

Reduced Maintenance

Servo-driven machines typically have fewer mechanical components, resulting in lower maintenance requirements and downtime.

Customizable Control

Advanced control systems allow for customization of molding processes, optimizing performance for specific applications and materials.

Improved Safety

Servo injection molding machines often feature advanced safety features such as emergency stop buttons, safety doors, and interlocks to protect operators and prevent accidents.

Advantages of Servo Injection Moulding Machine

Servo injection molding machines offer numerous advantages that make them the preferred choice for manufacturers:

- Energy Efficiency: Servo motors optimize energy consumption by adjusting speed and torque according to the actual demand, resulting in significant energy savings compared to traditional hydraulic systems.

- Precision and Accuracy: Servo-driven systems provide precise control over the injection speed, pressure, and position, ensuring consistent and high-quality molded parts with minimal variations.

- Faster Cycle Times: The ability to accelerate and decelerate rapidly allows servo machines to achieve shorter cycle times, increasing productivity and reducing manufacturing costs.

- Reduced Noise Levels: Servo motors operate more quietly than hydraulic counterparts, creating a quieter and more comfortable working environment for operators.

- Enhanced Reliability: With fewer mechanical components and reduced wear and tear, servo injection molding machines offer improved reliability and require less maintenance over their lifespan.

- Versatility: Servo technology enables flexibility in molding various types of materials and complex shapes, catering to a wide range of product specifications and production requirements.

- Improved Safety: Advanced control systems and safety features ensure safer operation and minimize the risk of accidents in the manufacturing environment.

FAQ'S To Servo Injection Molding Machine Manufacturer in Jharkhand

-

What is a servo injection molding machine?A servo injection molding machine is a type of injection molding machine that utilizes servo motors for precise control of the molding process. These machines offer improved energy efficiency, accuracy, and repeatability compared to traditional hydraulic or mechanical machines.

-

What are the advantages of servo injection molding machines?Servo injection molding machines offer several advantages, including higher energy efficiency, reduced cycle times, improved precision and accuracy in molding, lower maintenance requirements, and quieter operation compared to traditional machines.

-

How do servo injection molding machines contribute to energy savings?Servo motors used in these machines only consume energy when needed, unlike traditional hydraulic systems which continuously consume energy even when the machine is idle. This results in significant energy savings, especially in applications with varying load requirements.

-

What types of products are suitable for manufacturing with servo injection molding machines?Servo injection molding machines are suitable for a wide range of products across various industries, including automotive components, consumer goods, electronics, medical devices, and packaging materials, among others.

-

What customization options are available for servo injection molding machines?Manufacturers often offer customization options such as varying injection capacities, clamping forces, shot sizes, and mold sizes to meet the specific requirements of different applications and industries.