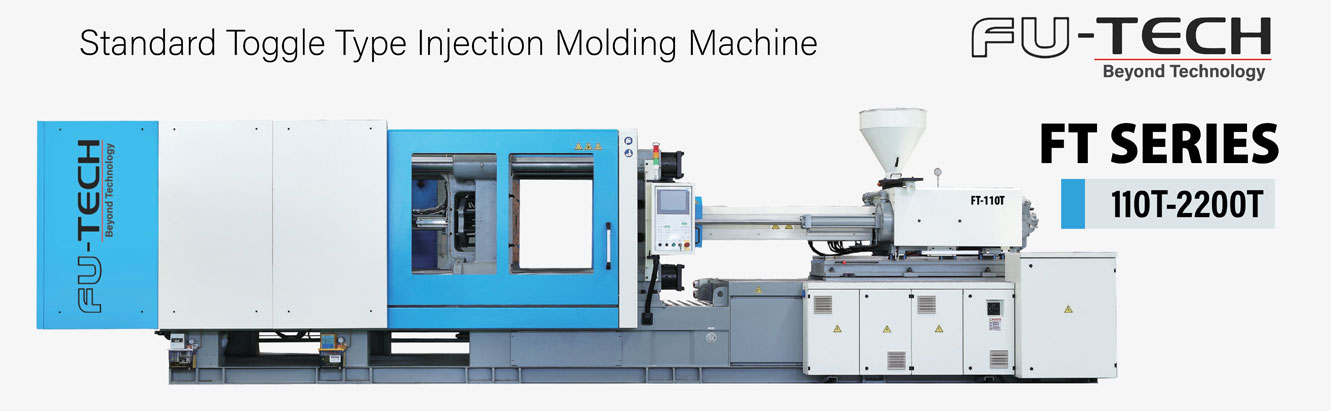

FT Series standard toggle type injection moulding machine

In today's demanding manufacturing landscape, achieving peak performance and unwavering quality is no longer a luxury, it's a necessity. Introducing the FT Series toggle-type injection molding machine from Ftech Machinery – a game-changer meticulously crafted to deliver exceptional precision, unmatched production output, and long-lasting reliability for large-scale applications.

The FT Series isn't just a machine; it's a strategic investment. With over 20 years of experience and cutting-edge technology, we've designed it to empower you to:

- Achieve Impeccable Precision: Experience the pinnacle of molding accuracy. The FT Series features a state-of-the-art servo system and meticulously engineered components, ensuring consistent, top-quality parts with every cycle.

- Unleash High-Volume Production: Fuel your production line. The FT Series boasts a robust build and a highly responsive hydraulic system, enabling you to churn out large parts at exceptional speeds.

- Minimize Downtime. Maximize Profits: Experience worry-free operation. The FT Series prioritizes reliability with top-tier hydraulic and electrical components, along with a modular design that simplifies maintenance and upgrades.

But that's not all. The FT Series boasts a comprehensive suite of advantages designed to elevate your molding experience:

- Unmatched Stability: Built to last. Over two decades of industry expertise are poured into the FT Series' design, guaranteeing unwavering stability and long-lasting performance for years to come.

- Energy Efficiency Redefined: Embrace sustainability without sacrificing power. The FT Series integrates a precise servo system and an optimally designed hydraulic circuit, delivering energy-saving capabilities that rival fully-electric machines.

- Effortless Maintenance: Keep your production flowing. The FT Series features a clean, maintenance-friendly design with a greaseless lubrication system for the injection unit and a user-friendly lubrication system for the platen, minimizing downtime for cleaning and maintenance.

- Cost-Effective Performance: Get the best of both worlds. The FT Series delivers exceptional performance that rivals international brands, all at a competitive price that maximizes your return on investment.

- Customizable Solutions: Tailored to your needs. The FT Series offers extensive customization options, allowing you to configure a machine that perfectly aligns with your unique molding requirements.

- User-Friendly Operation: Effortless control at your fingertips. The FT Series features an intuitive control system that simplifies operation for your team, maximizing efficiency and minimizing training time.

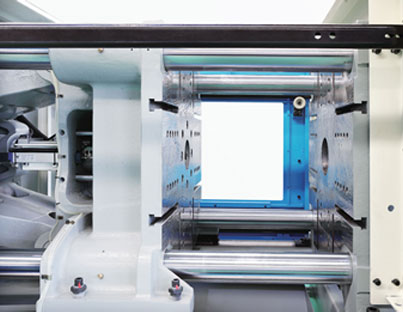

Direct Clamping

- Larger space between tie-bars, suitable for larger and multi-cavity molds.

- Longer and wider guide length, higher precision, improved product quality and mold working life.

- Graphite-Copper bushes in Tie-Bar, slider movable platen ensures fast and precise mold close and open.

- Better designed mechanical structure and toggle system for faster cycle time and improved production efficiency.

- European type Ejector System.

- Spacios structure design for upgrades and retrofits.

- Rigid platen and mechanical systems ensures longer machine life

Injection Unit

- Injection unit with dual precise linear guide rails, ensuring the best precision and fast speed.

- Dual carriage cylinders improve a better injection precision.

- No welding, Adaptor design ensures easier maintenace and repairs.

- Upturning designed nozzle cover make production and maintenance easier.

- Imported high quality SKD61 material ring, cone and plunger; lots of screw design can meet different plastic materials and special processing injection molding needs.

Hydraulic Unit

- Standard precise and energy saving Servo Motor System, energy saving capacity can reach to 20%-80% than traditional injection machine.

- Hydraulic parts from reputed brands ensure machine’s reliability and fast response time.

- Visible and dischargeable oil tank, easy for hydraulic maintenance.

- Modular adaptor valve blocks, hydraulic circuit and functions make upgrade and maintenance easy.

- Self-sealed magnetic suction filter, makes machine’s maintenance more convenient.

- Logical distribution of pump oil suction port, oil drain and hydraulic pipe fittings makes maintenance easier.

- Germany DIN standard hydraulic pipe fitting with seal, G screw thread style plug to avoid oil seepage.

Electric Unit

- Electric parts from reputed brands.

- High quality large colour screen controller with multiple languages.

- Standard equipped LED three-colour tower light with alarm, ensures clear visibility of machine status on shop floor.

- Modernized network management function available.

- Water-proof rubber seal used on electric cabinet ensure high safety.

- Machine program according to CE safety standard.

Technical Specifications of FT Series - 110-150 Injection Moulding Machine

| Description | Unit | FT-110 | FT-150 | ||||

| Injection Unit | A | B | C | A | B | C | |

| Screw Diameter | mm | 32 | 35 | 38 | 38 | 42 | 45 |

| Screw L/D Ratio | L/D | 25 | 22.8 | 21 | 25 | 22.7 | 21 |

| Shot Volume (Theoretical) | cm³ | 137 | 164 | 193 | 227 | 277 | 318 |

| Shot Weight (PS) | g | 125 | 149 | 175 | 206 | 252 | 289 |

| Injection Rate | g/s | 93 | 112 | 132 | 112 | 137 | 157 |

| Injection Pressure | Kg/cm2 | 2278 | 1904 | 1615 | 2376 | 1945 | 1695 |

| Screw Speed | rpm | 220 | 220 | ||||

| Clamping Unit | |||||||

| Clamping Force | kN | 1100 | 1500 | ||||

| Opening Stroke | mm | 360 | 380 | ||||

| Tie Bar Distance (HxV) | mm | 420 370 | 470x420 | ||||

| Max. Mold Height | mm | 400 | 500 | ||||

| Min. Mold Height | mm | 150 | 160 | ||||

| Ejector Stroke | mm | 100 | 120 | ||||

| Ejector Force | kN | 38 | 50 | ||||

| Others | |||||||

| Pump/Motor Power | kW | 15 | 18.7 | ||||

| Heater Power | kW | 8.1 | 12.2 | ||||

| Machine Dimensions (LxWxH) | Meter | 4.4x1.2x1.6 | 4.6x13x17 | ||||

| Machine Weight | ton | 3.8 | 4.5 | ||||

| Oil Tank Capacity | L | 200 | 250 | ||||

Technical Specifications of FT Series - 180-250 Injection Moulding Machine

| Description | Unit | FT-180 | FT-250 | ||||

| Injection Unit | A | B | C | A | B | C | |

| Screw Diameter | mm | 42 | 45 | 50 | 50 | 55 | 60 |

| Screw L/D Ratio | L/D | 23 | 21.6 | 19.4 | 23.4 | 21 | 19.5 |

| Shot Volume (Theoretical) | cm³ | 311 | 357 | 441 | 471 | 590 | 678 |

| Shot Weight (PS) | g | 283 | 325 | 401 | 428 | 518 | 617 |

| Injection Rate | g/s | 131 | 150 | 186 | 185 | 224 | 266 |

| Injection Pressure | Kg/cm2 | 2030 | 1769 | 1432 | 2094 | 1731 | 1454 |

| Screw Speed | rpm | 185 | 200 | ||||

| Clamping Unit | |||||||

| Clamping Force | kN | 1800 | 2500 | ||||

| Opening Stroke | mm | 435 | 492 | ||||

| Tie Bar Distance (HxV) | mm | 530 x 470 | 575 x 525 | ||||

| Max. Mold Height | mm | 550 | 580 | ||||

| Min. Mold Height | mm | 200 | 220 | ||||

| Ejector Stroke | mm | 140 | 150 | ||||

| Ejector Force | kN | 53 | 70 | ||||

| Others | |||||||

| Pump/Motor Power | kW | 23 | 30 | ||||

| Heater Power | kW | 13.8 | 18.35 | ||||

| Machine Dimensions (LxWxH) | Meter | 5.2x1.4x1.8 | 5.9x16x2.0 | ||||

| Machine Weight | ton | 5.5 | 7.5 | ||||

| Oil Tank Capacity | L | 250 | 300 | ||||

Technical Specifications of FT Series- 280-350 Injection Moulding Machine

| Description | Unit | FT-280 | FT-350 | ||

| Injection Unit | A B C | A | B | C | |

| Screw Diameter | mm | 55 60 65 | 65 | 70 | 75 |

| Screw L/D Ratio | L/D | 23 21 19.5 | 23.6 | 22 | 20.5 |

| Shot Volume (Theoretical) | cm³ | 665 792 929 | 1161 | 1346 | 1545 |

| Shot Weight (PS) | g | 605 721 845 | 1056 | 1225 | 1406 |

| Injection Rate | g/s | 181 215 253 | 306 | 355 | 407 |

| Injection Pressure | Kg/cm2 | 2139 1797 1531 | 1978 | 1705 | 1485 |

| Screw Speed | rpm | 160 | 165 | ||

| Clamping Unit | |||||

| Clamping Force | kN | 2800 | 3500 | ||

| Opening Stroke | mm | 560 | 675 | ||

| Tie Bar Distance (HxV) | mm | 630 x 580 | 730 X 680 | ||

| Max. Mold Height | mm | 650 | 750 | ||

| Min. Mold Height | mm | 250 | 280 | ||

| Ejector Stroke | mm | 160 | 180 | ||

| Ejector Force | kN | 90 | 125 | ||

| Others | |||||

| Pump/Motor Power | kW | 30 | 45 | ||

| Heater Power | kW | 21.2 | 29.7 | ||

| Machine Dimensions (LxWxH) | Meter | 6.7x1.8x2.0 | 7.7 x 2.0 x 2.1 | ||

| Machine Weight | ton | 9 | 12.7 | ||

| Oil Tank Capacity | L | 400 | 500 | ||

Technical Specifications of FT Series- 450-550 Injection Moulding Machine

| Description | Unit | FT-450 | FT-550 | ||||

| Injection Unit | A | B | C | A | B | C | |

| Screw Diameter | mm | 70 | 75 | 80 | 80 | 85 | 90 |

| Screw L/D Ratio | L/D | 23.6 | 22 | 20.6 | 21.3 | 20 | 18.9 |

| Shot Volume (Theoretical) | cm³ | 1519 | 1744 | 1984 | 2215 | 2501 | 2797 |

| Shot Weight (PS) | g | 1382 | 1587 | 1805 | 2016 | 2276 | 2545 |

| Injection Rate | g/s | 317 | 364 | 414 | 401 | 453 | 508 |

| Injection Pressure | Kg/cm2 | 1911 | 1664 | 1463 | 1967 | 1742 | 1554 |

| Screw Speed | rpm | 155 | 135 | ||||

| Clamping Unit | |||||||

| Clamping Force | kN | 4500 | 5500 | ||||

| Opening Stroke | mm | 764 | 860 | ||||

| Tie Bar Distance (HxV) | mm | 780x730 | 880 x 830 | ||||

| Max. Mold Height | mm | 780 | 850 | ||||

| Min. Mold Height | mm | 300 | 350 | ||||

| Ejector Stroke | mm | 210 | 250 | ||||

| Ejector Force | kN | 125 | 150 | ||||

| Others | |||||||

| Pump/Motor Power | kW | 45 | 52 | ||||

| Heater Power | kW | 32.1 | 41.5 | ||||

| Machine Dimensions (LxWxH) | Meter | 8.2x2.0x2 2.2 | 9.1x 2.2 X 2.2 | ||||

| Machine Weight | ton | 16.8 | 22 | ||||

| Oil Tank Capacity | L | 600 | 800 | ||||

Technical Specifications of FT Series- 700-850 Injection Moulding Machine

| Description | Unit | FT-700 | FT-850 | ||||||

| Injection Unit | A | B | C | D | A | B | c | D | |

| Screw Diameter | mm | 85 | 90 | 95 | 100 | 90 | 100 | 110 | 120 |

| Screw L/D Ratio | L/D | 23.3 | 22 | 20.8 | 20.8 | 24.4 | 22 | 20 | 18.3 |

| Shot Volume (Theoretical) | cm³ | 2835 | 3179 | 3542 | 3925 | 2990 | 3691 | 4467 | 5316 |

| Shot Weight (PS) | g | 2580 | 2893 | 3223 | 3572 | 2721 | 3359 | 4065 | 4837 |

| Injection Rate | g/s | 480 | 538 | 599 | 664 | 573 | 707 | 855 | 1018 |

| Injection Pressure | Kg/cm2 | 2020 | 1800 | 1620 | 1450 | 2190 | 1780 | 1470 | 1230 |

| Screw Speed | rpm | 135 | 110 | ||||||

| Clamping Unit | |||||||||

| Clamping Force | kN | 7000 | 8500 | ||||||

| Opening Stroke | mm | 970 | 1040 | ||||||

| Tie Bar Distance (HxV) | mm | 970 | x 920 | 1020 x 980 | |||||

| Max. Mold Height | mm | 980 | 1000 | ||||||

| Min. Mold Height | mm | 380 | 450 | ||||||

| Ejector Stroke | mm | 260 | 280 | ||||||

| Ejector Force | kN | 207 | 186 | ||||||

| Others | |||||||||

| Pump/Motor Power | kW | 37+37 | 45 45 | ||||||

| Heater Power | kW | 44.3 | 50.2 | ||||||

| Machine Dimensions (LxWxH) | Meter | 10.3x23x27 | 11.2x 2.5 x 3.3 | ||||||

| Machine Weight | ton | 32 | 37 | ||||||

| Oil Tank Capacity | L | 900 | 1000 | ||||||

Technical Specifications of FT Series- 1000-1300 Injection Moulding Machine

| Description | Unit | FT-1000 | FT-1300 | ||||||

| Injection Unit | A | B | C | D | A | B | C | D | |

| Screw Diameter | mm | 90 | 100 | 110 | 115 | 110 | 115 | 120 | 125 |

| Screw L/D Ratio | L/D | 25.5 | 23 | 20.9 | 20 | 23 | 22 | 21 | 20.2 |

| Shot Volume (Theoretical) | cm³ | 2988 | 3689 | 4464 | 4879 | 5270 | 5760 | 6272 | 6805 |

| Shot Weight (PS) | g | 2719 | 3356 | 4062 | 4440 | 4796 | 5242 | 5707 | 6193 |

| Injection Rate | g/s | 590 | 729 | 880 | 960 | 793 | 867 | 944 | 1024 |

| Injection Pressure | Kg/cm2 | 2160 | 1760 | 1460 | 1330 | 1860 | 1700 | 1560 | 1440 |

| Screw Speed | rpm | 100 | 90 | ||||||

| Clamping Unit | |||||||||

| Clamping Force | kN | 10000 | 13000 | ||||||

| Opening Stroke | mm | 1120 | 1320 | ||||||

| Tie Bar Distance (HxV) | mm | 1080 x 1080 | 1350 x 1350 | ||||||

| Max. Mold Height | mm | 1100 | 1300 | ||||||

| Min. Mold Height | mm | 400 | 550 | ||||||

| Ejector Stroke | mm | 325 | 380 | ||||||

| Ejector Force | kN | 210 | 245 | ||||||

| Others | |||||||||

| Pump/Motor Power | kW | 45 55 | 37 + 37 + 37 | ||||||

| Heater Power | kW | 63.9 | 74.4 | ||||||

| Machine Dimensions (LxWxH) | Meter | 11.9x 2.7 X 3.3 | 12.9 x 2.8 x 3.3 | ||||||

| Machine Weight | ton | 42 | 59 | ||||||

| Oil Tank Capacity | L | 1700 | 2100 | ||||||

Why Choose Futech FT Series?

Simple. We don't just sell machines, we build partnerships. The FT Series is more than just a piece of equipment; it's a gateway to achieving peak molding performance and propelling your business to new heights. With Futech, you benefit from:

- Unwavering Commitment to Quality: We prioritize exceptional craftsmanship and rigorous quality control procedures, ensuring you receive a machine built to last.

- Unparalleled Expertise: Our team of seasoned engineers, with an average of over 15 years of experience, are dedicated to providing you with expert advice and support.

- 24/7 Service Network: Experience peace of mind. We offer a comprehensive service network with readily available spare parts and a team of highly trained service engineers to ensure minimal downtime.

- Collaborative Innovation: We actively engage with our customers to understand their evolving needs and continuously refine our technology to deliver the best possible solutions.

Ready to unlock the true potential of your large-scale molding operations? Contact Futech Machinery today. Explore the FT Series and discover how it can transform your production into a powerhouse of precision, efficiency, and profitability.