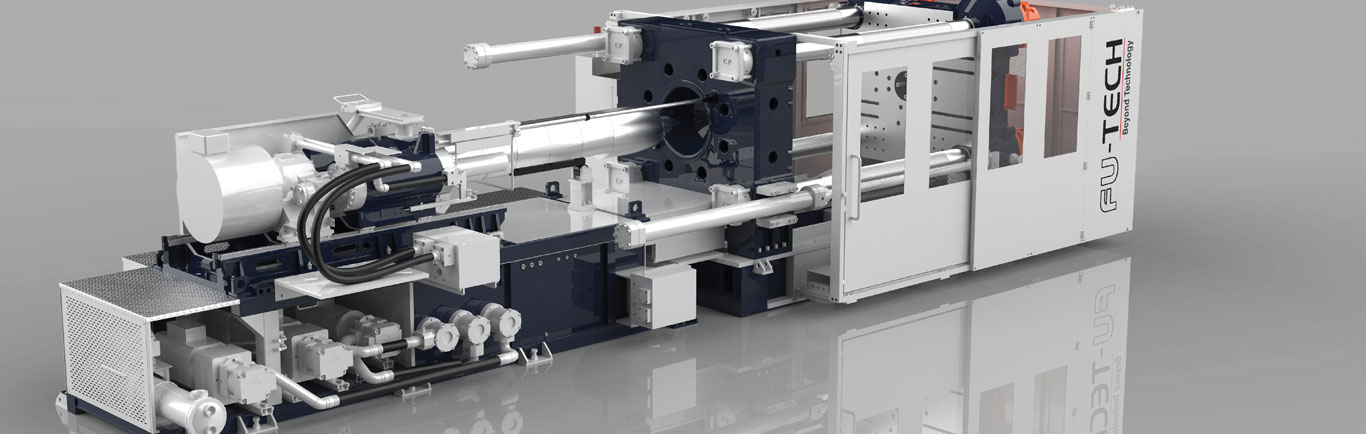

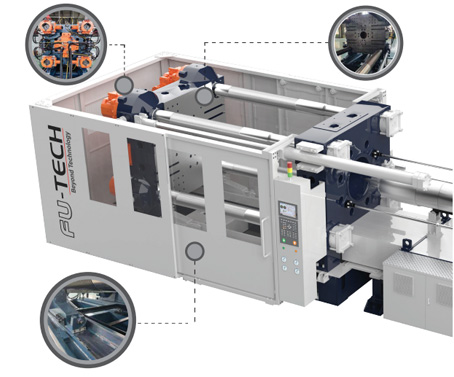

Futech TP Series Injection Molding Machine

Take on large-scale molding projects with unwavering confidence. The Futech TP Series injection molding machine is a powerhouse engineered to tackle your most demanding applications. With over 20 years of experience and cutting-edge technology, the TP Series delivers exceptional quality, unmatched stability, and energy-efficient performance – all at a competitive price.

Experience exceptional precision and repeatability on every run, ensuring consistent, high-quality results. But the TP Series doesn't stop there. It's also a champion of energy efficiency, utilizing an advanced servo system that significantly reduces energy consumption compared to traditional hydraulic machines. This translates to lower operating costs and a smaller environmental footprint.

The TP Series understands that your needs are unique. That's why Futech offers a wide range of customization options, allowing us to tailor the machine to your specific requirements. Unwavering reliability is paramount, so the TP Series incorporates top-tier hydraulic and electric components from renowned brands. Additionally, key parts mirror those used by leading international IMM manufacturers, providing you with peace of mind and long-term performance. Effortless control and a user-friendly interface minimize training time and maximize operator efficiency. Embrace the power to conquer large-scale molding challenges with confidence. Choose the Futech TP Series.

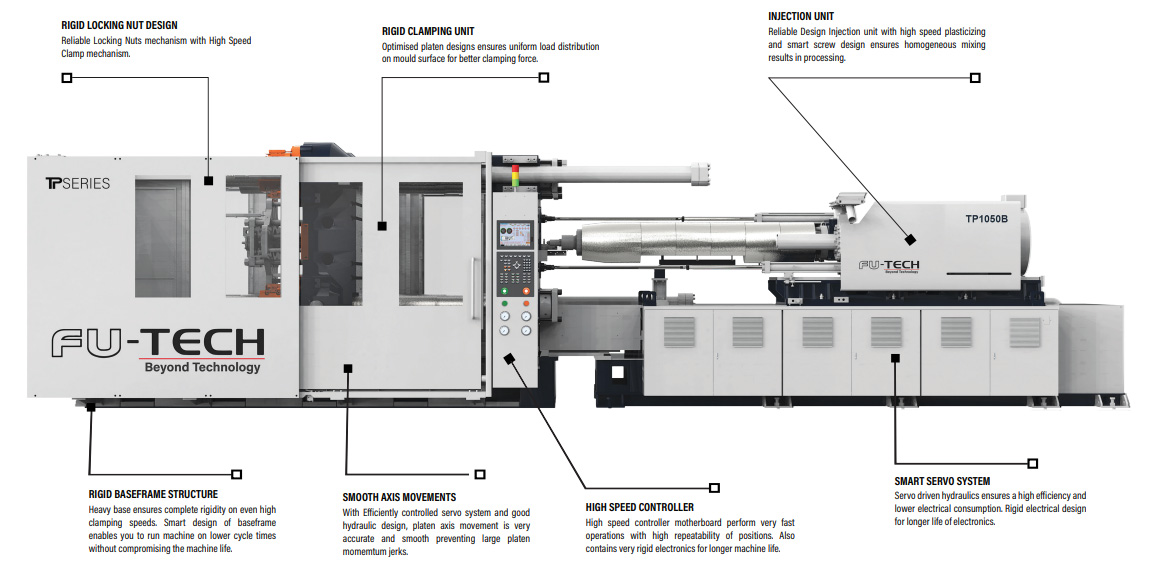

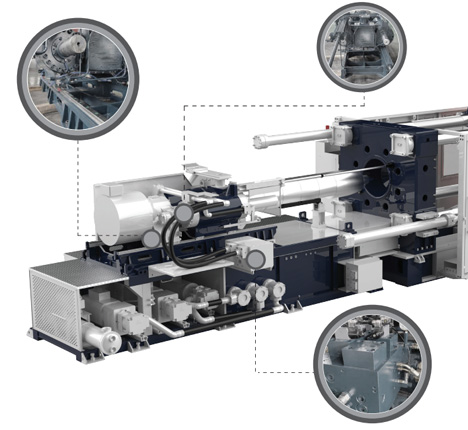

Hydraulic System

- Fast reponse logical valve with large flow cross section contrubution to better stability and control of hydraulics.

- Quick and stable mould height adjustment.

- All hydraulics hoses with european regulations.

- Easy repair and maintenance.

- Different from traditional proportional pump, our machines can save 30% to 70% power by servo system depending on applications.

Clamping Unit

- Four clamping cylinders with average output to reduce product shrinkage and deformation.

- Large space between tie bar and long distance of opening stroke which is epecially good for products with big or deep size.

- Sliding foot design, stable action and easy maintenance and adjustment.

Injection Unit

- The high rigid linear guideway realized its function of lower resistance and ensures the injection unit stable and durable.

- The injection unit is stable and accuracy by applying double cylinders.

- Proportional valve controls the back pressure for highly precise production.

Control System

- Easy to operate.

- Clear function on panel.

- Stable and reliable quality.

- Networking and monitoring.

- High speed servo system with better control and accuracy.

- Precise and accurate advanced controller.

- Multi stage linear axis movement control for positions.

Technical Specifications of TP Series Injection Moulding Machine

| MODEL | Unit | TP-650B | TP-850B | TP-1050B | TP-1450B | TP-1750B | ||||||||||

| A | B | C | A | B | C | A | B | C | A | B | C | A | B | C | ||

| Screw Diameter | mm | 80 | 85 | 90 | 90 | 100 | 110 | 100 | 110 | 120 | 110 | 120 | 130 | 130 | 140 | 150 |

| Injection Pressure | kg/cm2 | 2231 | 1976 | 1762 | 2283 | 1849 | 1528 | 2290 | 1893 | 1590 | 2149 | 1806 | 1539 | 1738 | 1498 | 1305 |

| Theoretical Shot Volume | cm³ | 2312 | 2610 | 2926 | 3180 | 3927 | 4751 | 4712 | 5701 | 6785 | 5702 | 6786 | 7963 | 9954 | 11545 | 13253 |

| of | g | 2080 | 2349 | 2633 | 2863 | 3534 | 4376 | 4241 | 5131 | 6107 | 5132 | 6107 | 7167 | 8959 | 10390 | 11928 |

| (PS)/Shot Weight of Injection | OZ | 73 | 83 | 93 | 101 | 125 | 151 | 149 | 181 | 215 | 181 | 216 | 254 | 316 | 367 | 421 |

| Injection Rate | cm3/s | 528 | 596 | 668 | 643 | 793 | 960 | 796 | 963 | 1147 | 985 | 1173 | 1377 | 1314 | 1524 | 1750 |

| Plasticizing Rate | kg/hr | 210 | 243 | 276 | 235 | 312 | 395 | 312 | 395 | 497 | 344 | 432 | 512 | 512 | 594 | 711 |

| Injection Speed | mm/s | 105 | 101 | 101 | 104 | 99 | ||||||||||

| Screw Speed | rpm | 135 | 115 | 115 | 100 | 100 | ||||||||||

| Mold Clamping Force | Ton | 650 | 850 | 1050 | 1450 | 1750 | ||||||||||

| Distance Between Tie Bars | mm | 960x860 | 1100x960 | 1210x1060 | 1410x1210 | 1600x1400 | ||||||||||

| Mold Platen Size | mm | 1300x1250 | 1550x1500 | 1760x1760 | 2000x1800 | 2300x2100 | ||||||||||

| Mold Thickness | mm | 400-900 | 500-1100 | 600-1300 | 650-1400 | 700-1500 | ||||||||||

| MAX. Daylight | mm | 1800 | 2300 | 2800 | 3000 | 3200 | ||||||||||

| Mold Locating Ring | mm | 150 | 150 | 150 | 150 | 150 | ||||||||||

| Ejector Stroke | mm | 220 | 300 | 300 | 350 | 350 | ||||||||||

| Ejector Force | Ton | 12 | 17 | 20 | 20 | 20 | ||||||||||

| Number of Temp Control Zone | Zone | 7 | 7 | 7 | 7 | 7 | ||||||||||

| Motor Power | kw | 41x2 | 41x1+57x1 | 41x3 | 41x2+57x1 | 41x1+57x2 | ||||||||||

| Heating Capacity | kw | 28 | 45 | 45 | 60 | 75 | ||||||||||

| System Pressure | kg/cm2 | 170 | 170 | 170 | 170 | 170 | ||||||||||

| Oil Tank Capacity | L | 800 | 1000 | 1300 | 2000 | 2000 | ||||||||||

| Machine Diamension (LxWxH) | m | 7.5x2.4x2.3 | 8.6x2.7x2.5 | 10x3.0x2.62 | 11x3.0x2.85 | 12x3.7x2.15 | ||||||||||

| Machine Weight (about) | Ton | 24 | 32 | 40 | 60 | 80 | ||||||||||

| MODEL | Unit | TP-2200B | TP-2750B | TP-3500B | TP-4000B | ||||||||

| A | B | C | A | B | C | A | B | C | A | B | C | ||

| Screw Diameter | mm | 140 | 150 | 160 | 140 | 150 | 160 | 160 | 170 | 180 | 200 | 220 | 240 |

| Injection Pressure | kg/cm | 1942 | 1692 | 1487 | 1942 | 1692 | 1487 | 2279 | 2018 | 1800 | 2098 | 1734 | 1460 |

| Theoretical Shot Volume | cm3 | 12315 | 14137 | 16084 | 16001 | 18369 | 20900 | 21714 | 24513 | 27482 | 37070 | 44855 | 53381 |

| of | g | 11083 | 12723 | 14476 | 14401 | 16532 | 18809 | 19543 | 22062 | 24734 | 33734 | 40818 | 48576 |

| (PS)/Shot Weight of Injection | oz | 391 | 449 | 511 | 509 | 584 | 665 | 690 | 779 | 875 | 1190 | 1439 | 1713 |

| Injection Rate | cm3/s | 1442 | 1655 | 1883 | 1458 | 1674 | 1904 | 1777 | 2006 | 2250 | 2026 | 2452 | 2918 |

| Plasticizing Rate | kg/hr | 475 | 568 | 647 | 475 | 568 | 647 | 647 | 767 | 859 | 695 | 917 | 1091 |

| Injection Speed | mm/s | 94 | 94 | 88 | 54 | ||||||||

| Screw Speed | rpm | 80 | 80 | 80 | 50 | ||||||||

| Mold Clamping Force | Ton | 2200 | 2750 | 3500 | 4000 | ||||||||

| Distance Between Tie Bars | mm | 1800x1500 | 2000x1600 | 2200x1800 | 2420x2020 | ||||||||

| Mold Platen Size | mm | 2600x2300 | 2900x2500 | 3200x2800 | 3350x2950 | ||||||||

| Mold Thickness | mm | 900-1700 | 900-1900 | 1000-2100 | 1100-2200 | ||||||||

| MAX. Daylight | mm | 3400 | 3600 | 3800 | 4200 | ||||||||

| Mold Locating Ring | mm | 150 | 315 | 315 | 315 | ||||||||

| Ejector Stroke | mm | 400 | 400 | 400 | 550 | ||||||||

| Ejector Force | Ton | 40 | 40 | 40 | 68 | ||||||||

| Number of Temp Control Zone | Zone | 7 | 7 | 8 | 8 | ||||||||

| Motor Power | kw | 23x1+57x3 | 23x1+57x3 | 57x5 | 48x6 | ||||||||

| Heating Capacity | kw | 90 | 90 | 105 | 240 | ||||||||

| System Pressure | kg/cm | 170 | 170 | 170 | 170 | ||||||||

| Oil Tank Capacity | L | 2600 | 2600 | 3000 | 4000 | ||||||||

| Machine Diamension (LxWxH) | m | 13.55x4.08x3.4 | 15x4.45x3.7 | 17x4,8x4.0 | 21x5.6x5.6 | ||||||||

| Machine Weight (about) | Ton | 105 | 135 | 180 | 255 | ||||||||

Why Choose Futech for the TP Series Injection Molding Machine?

- Large-Scale Powerhouse: The TP Series tackles your most demanding projects with a robust two-platen design and generous tie-bar distance, ideal for massive and intricate molds.

- Unwavering Precision & Repeatability: Experience consistent, high-quality results with exceptional precision and repeatability for every run.

- Energy Efficiency Champion: Minimize your environmental impact and operating costs. The TP Series' advanced servo system significantly reduces energy consumption compared to traditional machines.

- Future-Proofed with Modular Design: Evolve with your needs. The TP Series' modular design allows for effortless upgrades and retrofits, keeping your machine adaptable for years to come.

- Customizable Solutions: Get the perfect fit for your application. Futech offers a wide range of customization options to tailor the TP Series to your specific molding requirements.

- Unparalleled Reliability: Confidence is key. The TP Series utilizes top-tier hydraulic and electric components from renowned brands, ensuring long-term performance and peace of mind.

- Clean Production Environment: Maintain a pristine workspace with the TP Series' maintenance-free lubrication system and grease lubrication combination, ideal for even the most demanding applications.

- Effortless Operation: Minimize training time and maximize operator efficiency with the user-friendly touchscreen interface.

- Trusted Partner: Futech Machinery is dedicated to your success. The TP Series is your reliable partner for tackling large-scale molding projects with confidence.