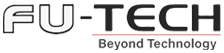

Forge Ahead with Forza Injection Molding Machine:

Your Gateway to High-Performance Injection Molding

Tired of settling for average? In today's competitive manufacturing landscape, achieving peak performance is no longer optional. Introducing the Futech’s Forza Series, the injection molding machine designed to propel you to the forefront of your industry.

The Forza Series isn't just a machine; it's a strategic partner. We've meticulously crafted it to deliver unparalleled precision, efficiency, and unwavering reliability, ensuring every single molded part meets your exacting standards.

Here's how the Forza Series empowers you to dominate:

- Unleash Flawless Production Runs: Experience the unwavering strength of the Forza Series. A robust direct clamping mechanism and high-strength machine base minimize vibrations and jerks, guaranteeing exceptional repeatability for consistent, error-free production runs.

- Hygiene Redefined: The Forza Series prioritizes cleanliness. The adjustable taper tray seamlessly adapts to your mold needs, while the stainless steel covers provide superior hygiene – ideal for food-grade and medical applications where contamination is a critical concern.

- Precision Injection. Every Time: Say goodbye to inconsistencies. The Forza Series boasts frictionless linear guide rails on the injection unit, ensuring high-speed, accurate injection every single cycle. The result? Flawless molding and consistent product quality.

- Effortless Maintenance. Maximum Uptime: The Forza Series prioritizes efficiency. The upturning purge safety guard simplifies barrel purging and cleaning, minimizing downtime. Plus, the easy-slide hopper allows effortless movement, even with a fully loaded hopper-dryer. Focus on production, not maintenance headaches.

- Cool Confidence. Uninterrupted Performance: Don't let soaring temperatures disrupt your workflow. The Forza Series features a specially designed heat exchanger with fins, guaranteeing optimal cooling even in extreme environments. This translates to longer machine life, reduced energy consumption, and unwavering performance.

- The Power of Servo-Hydraulic Technology: Experience a new level of control. The Forza Series integrates a cutting-edge servo-hydraulic system, delivering a precise and high-repeatability cycle. Faster moving platen movements with exceptional control of speed and pressure optimize your production output, maximizing efficiency.

But that's not all. The Forza Series boasts a comprehensive suite of features designed to elevate your molding experience:

- Advanced Mold Protection: Protect your valuable investments. The exceptional and responsive mold protection feature safeguards your molds, minimizing the risk of damage and costly repairs.

- Unparalleled Flexibility: Accommodate even the most demanding applications. The generous tie bar distance allows you to handle larger hot runner molds, ensuring your machine adapts to your evolving needs.

- Superior Defect Control: Deliver flawless products consistently. The multi-stage holding pressure control feature ensures optimal pressure throughout the molding cycle, minimizing defects and maximizing product quality.

- Intuitive Control at Your Fingertips: Effortless monitoring and adjustments. The Forza Series integrates an accurate linear position sensor and a user-friendly controller screen, providing you with complete control over your molding process.

Ready to unlock the true potential of your molding operations? Contact Futech Machinery today. Explore the Forza Series and discover how it can transform your production into a high-performance powerhouse. Don't settle for anything less than the best. Choose Forza. Choose excellence.

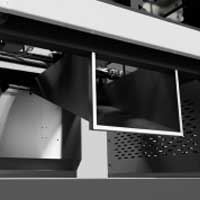

Direct Clamping

- Direct Locking Centre Clamping Mechanism Designed for Robust Life and High Repeatability.

- High Strength Machine Base optimized for Reduced Vibrations and Jerks.

- Excellent and Responsive Mold Protection feature, Optimized for Sensing Small Particle.

- A Large Tie Bar Distance can Accommodate Demand for larger size Hot Runner Moulds.

- Dent Proof Long Life Hardened Chrome Plated Tie Bars which offer Maximum life of Guide Bushings.

- Accurate Tonnage Delivery to Mould.

- Auto Lubrication on Tie-Bar enhancing friction-less Movement of Moving Platen.

- Wide Space for Part Collection and Dropping.

- Rigid Oil Sealing Design on Ram for leak proof operation.

- Better and Uniform Strain Distribution on Tie Rods because of Perfect Parallelism offered in comparison with other machines.

- Faster Moving Platen Movement with Excellent Control of Speed and Pressure.

Injection Unit

- Cold Start Protection.

- High Accuracy Linear Position Sensor.

- Accurate Proportional back pressure Control from controller screen.

- Easy to Push Sliding Hopper Mechanism for easy Maintenance.

- Multi-Stage Holding Pressure Control offers better defect control.

- High Quality SSR Control Ceramic Heater bands.

- High Screw Speed in comparison to standard machines

- Multi-step Screw refilling RPM Control.

- Nozzle Contact Force by pressure Switch.

Servo Hydraulic

Precise Cycle and High Repeatability by a Closed Loop ServoSystem.

Noise Reduction in Hydraulic circuit in comparison to other machines.

Increased reliability and low maintenance of complete hydraulic system.

Easy to access design of Hydraulics for maintenance.

High Quality Return line filter offers clean oil supply to pump.

More Usage of Hoses for better Hydraulic damping and low pressure drops.

Fast Response Hydraulic Valves and other Equipements for better cycle time.

Very High Acceleration and Better deceleration of moving platen.

Reduced energy consumption due to low pressure drop in Hydraulic circuit.

High Damping Hydraulic Circuit - Very low Jerks and Vibrations of Hydraulic Valves.

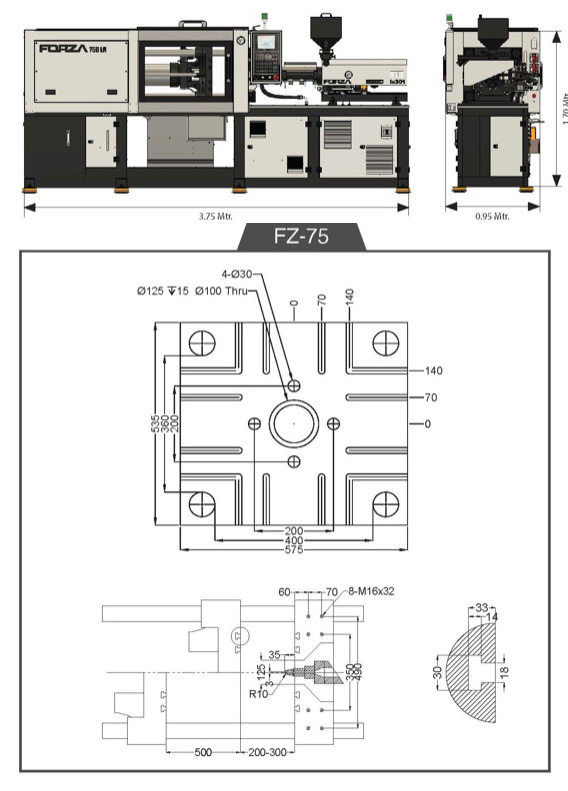

Technical Specifications of Forza Series- 75 Injection Moulding Machine

| IU-301 | ||||

| A | B | C | ||

| Screw Dia | mm | 30 | 35 | 40 |

| LD Ratio | 25 | 21 | 18 | |

| Screw Stroke | mm | 150 | 150 | 150 |

| Screw Speed | rpm | 325 | 325 | 325 |

| Injection Capacity | cm³ | 106 | 144 | 189 |

| Injection Pressure | kg/cm2 | 2836 | 2083 | 1595 |

| Injection Rate | cc/sec | 61 | 83 | 109 |

| Nozzle Force | kN | 43 | 43 | 43 |

| Heating Capacity | kW | 8 | 8 | 8 |

| Clamping Force | kN | 750 | ||

| Opening Stroke | mm | 500 | ||

| Tie Bar Distance | mm | 400 X 360 | ||

| Min. Mold Height | mm | 200/300 | ||

| Total Day Light | mm | 700 / 800 | ||

| Ejector Stroke | mm | 100 | ||

| Ejector Force | kN | 31 | ||

| Pump/Motor Power | kW | 12 | ||

| Oil Tank Capacity | L | 280 | ||

| Machine Dimensions | m | 3.75 X 0.95 X 1.7 | ||

| Machine Weight | Ton | 3.5 | ||

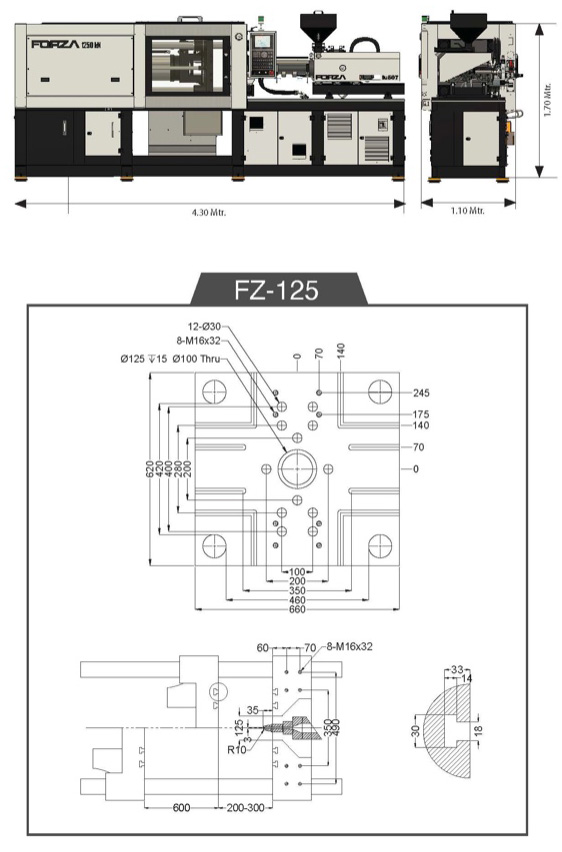

Technical Specifications of Forza Series- 125 Injection Moulding Machine

| IU-507 | ||||

| A | B | C | ||

| Screw Dia | mm | 35 | 40 | 45 |

| LD Ratio | 24 | 21 | 19 | |

| Screw Stroke | mm | 200 | 200 | 200 |

| Screw Speed | rpm | 333 | 333 | 333 |

| Injection Capacity | cm³ | 193 | 251 | 318 |

| Injection Pressure | kg/cm² | 2632 | 2015 | 1592 |

| Injection Rate | cc/sec | 101 | 132 | 167 |

| Nozzle Force | kN | 67 | 67 | 67 |

| Heating Capacity | kW | 9.5 | 9.5 | 9.5 |

| Clamping Force | kN | 1250 | ||

| Opening Stroke | mm | 600 | ||

| Tie Bar Distance | mm | 460 X 420 | ||

| Min. Mold Height | mm | 200/300 | ||

| Total Day Light | mm | 800 / 900 | ||

| Ejector Stroke | mm | 125 | ||

| Ejector Force | kN | 50 | ||

| Pump/Motor Power | kW | 18.5 | ||

| Oil Tank Capacity | L | 350 | ||

| Machine Dimensions | m | 4.3 X 1.1 X 1.7 | ||

| Machine Weight | Ton | 4.5 |

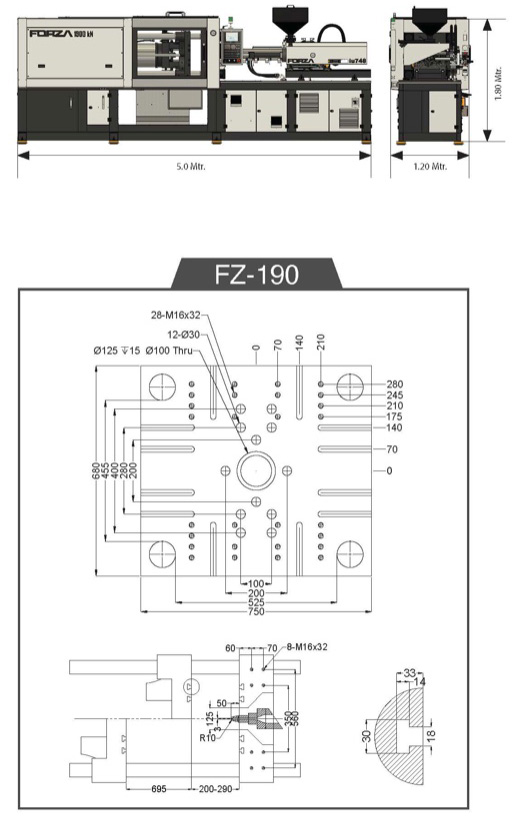

Technical Specifications of Forza Series- 190 Injection Moulding Machine

| IU-996 | ||||

| A | B | C | ||

| Screw Dia | mm | 45 | 50 | 55 |

| LD Ratio | 26 | 23 | 21 | |

| Screw Stroke | mm | 275 | 275 | 275 |

| Screw Speed | rpm | 300 | 300 | 300 |

| Injection Capacity | cm³ | 438 | 540 | 654 |

| Injection Pressure | kg/cm2 | 2276 | 1843 | 1523 |

| Injection Rate | cc/sec | 176 | 217 | 263 |

| Nozzle Force | kN | 67 | 67 | 67 |

| Heating Capacity | kW | 16 | 16 | 16 |

| Clamping Force | kN | 1900 | ||

| Opening Stroke | mm | 695 | ||

| Tie Bar Distance | mm | 525 X 455 | ||

| Min. Mold Height | mm | 200/290 | ||

| Total Day Light | mm | 895 / 985 | ||

| Ejector Stroke | mm | 125 | ||

| Ejector Force | kN | 62 | ||

| Pump/Motor Power | kW | 21.5/28.3 | ||

| Oil Tank Capacity | L | 560 | ||

| Machine Dimensions | m | 5.0 X 1.2 X 1.8 | ||

| Machine Weight | Ton | 5.9 | ||

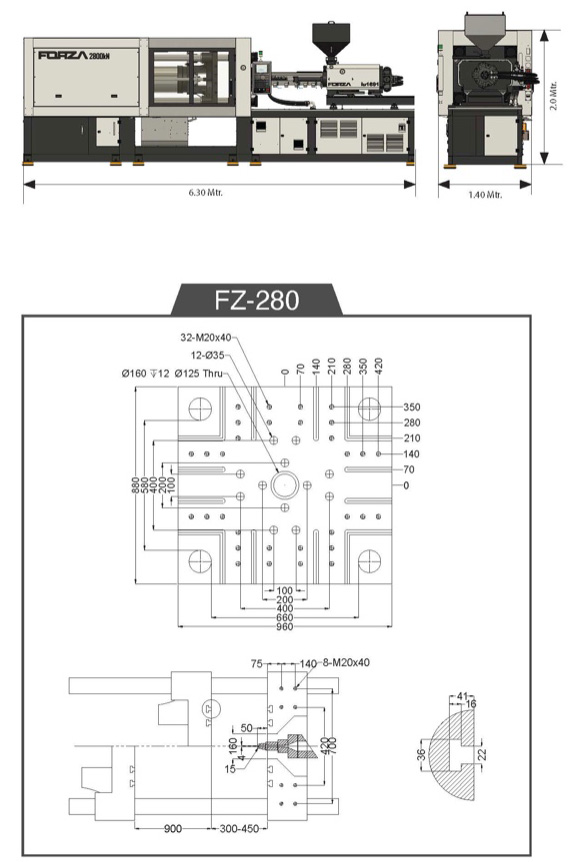

Technical Specifications of Forza Series- 280 Injection Moulding Machine

| IU-1691 | ||||

| A | B | C | ||

| Screw Dia | mm | 55 | 60 | 70 |

| LD Ratio | 27 | 22 | 19 | |

| Screw Stroke | mm | 325 | 325 | 325 |

| Screw Speed | rpm | 250 | 250 | 250 |

| Injection Capacity | cm³ | 772 | 919 | 1291 |

| Injection Pressure | kg/cm2 | 2190 | 1840 | 1352 |

| Injection Rate | cc/sec | 244 | 290 | 395 |

| Nozzle Force | kN | 83 | 83 | 83 |

| Heating Capacity | kW | 22.4 | 22.4 | 22.4 |

| Clamping Force | kN | 2800 | ||

| Opening Stroke | mm | 900 | ||

| Tie Bar Distance | mm | 660 X 580 | ||

| Min. Mold Height | mm | 300 / 450 | ||

| Total Day Light | mm | 1200/1350 | ||

| Ejector Stroke | mm | 180 | ||

| Ejector Force | kN | 80 | ||

| Pump/Motor Power | kW | 18.5 + 18.5 | ||

| Oil Tank Capacity | L | 840 | ||

| Machine Dimensions | m | 6.3 X 1.4 X 2.0 | ||

| Machine Weight | Ton | 10.5 | ||

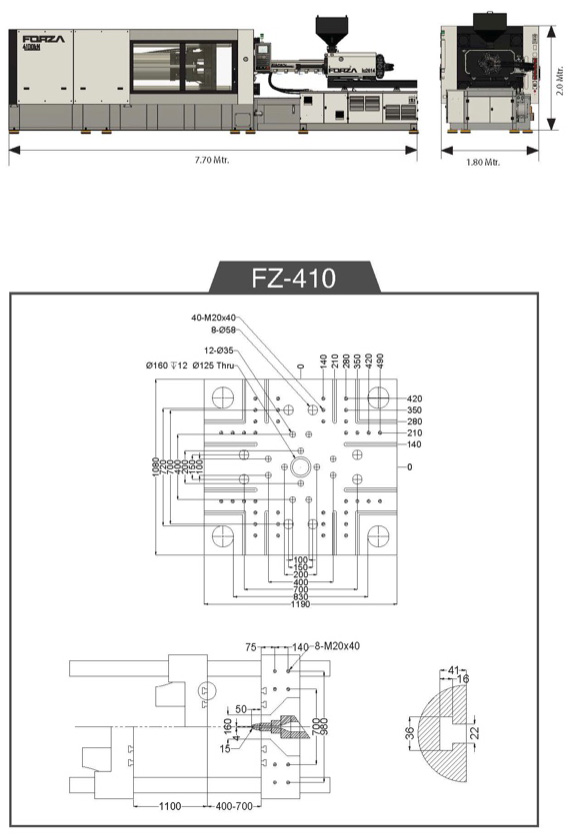

Technical Specifications of Forza Series- 410 Injection Moulding Machine

| IU-410 | ||||

| A | B | C | ||

| Screw Dia | mm | 60 | 70 | 80 |

| LD Ratio | 24 | 21 | 18 | |

| Screw Stroke | mm | 350 | 350 | 350 |

| Screw Speed | rpm | 218 | 218 | 218 |

| Injection Capacity | cm³ | 990 | 1348 | 1760 |

| Injection Pressure | kg/cm² | 2640 | 1940 | 1485 |

| Injection Rate | cc/sec | 242 | 330 | 431 |

| Nozzle Force | kN | 110 | 110 | 110 |

| Heating Capacity | kW | 27.7 | 27.7 | 27.7 |

| Clamping Force | kN | 4100 | ||

| Opening Stroke | mm | 1100 | ||

| Tie Bar Distance | mm | 830 X 720 | ||

| Min. Mold Height | mm | 400 / 700 | ||

| Total Day Light | mm | 1500/1800 | ||

| Ejector Stroke | mm | 200 | ||

| Ejector Force | kN | 126 | ||

| Pump/Motor Power | kW | 28.3 + 28.3 | ||

| Oil Tank Capacity | L | 1050 | ||

| Machine Dimensions | m | 7,7 X 1.8 X 2.0 | ||

| Machine Weight | Ton | 18.5 | ||

Features of Forza Series Injection Moulding Machine

| STANDARD FEATURES | ||

| Hybrid Servo System | Mould Gaurd Safety Feature | |

| Standard B Screw | Rear Door Handle | |

| Screw RPM Display | Water Manifold Standard 6-Zone | |

| Centralized Lubrication | Stainless Steel Part Drop Tray | |

| Proportional Back Pressure | Auto Screw Protection | |

| Hourly Power Consumption | Nozzle Contact Force by Pressure Switch for Main IU | |

| T-Slotted Platten | Cold Slug Removal by Extruder / Injection | |

| Hydraulic & Electric Safety | Actual Injection Speed & Pressure Graph Display | |

| Mould Clamp | Unlimited Mold Data Storage | |

| Inbuilt Toolbox | Choice of Multiple Languages | |

| Three Power Sockets | Energy Consumption Analysis | |

| Leveling Pad | High/Low Temperature Alarm | |

| Auto Lubrication | Leveling Pads | |

| Oil Collection Trays Moving Platen | Graphical Representation of Cycle Analysis | |

| Position Based Ramping forAccuratePositiion Switching, Precise Speed & Presssure Control | ||

| DataProtection with four level of access with Dynamic Password | ||

| OPTIONAL FEATURES | ||

| Ancillary Equipment | Variable Displacement Pump | |

| EUROMAP Interface | Double Core Pull | |

| Bi-Mettallic Screw Barrel | Double Air Ejection | |

| Sliding Top Cover | Infra-red Heaters | |

| Hopper Dryer | Close Loop Injection | |

| Heater Insulation | High Speed Injection | |

| Hydraulic Oil | Network Management System | |

| Part Drop Detect | Contactless Transducer for Clamp Position | |

| Layin Hopper Magnet | ||

| NozzelShut-offValve w/ Parallel Operation (Not for Glass Filled Material) | ||

| Proportional SpeedControlwith Operator Adjustable 5 Opening & 5 Closing Speed | ||

|

||

Why Choose Futech and the Forza Series?

- Uncompromising Durability: Robust construction with direct clamping mechanism minimizes vibrations and ensures exceptional repeatability.

- Hygiene at the Forefront: Adjustable taper tray and stainless steel covers prioritize cleanliness, perfect for food-grade and medical applications.

- Precision Injection. Every Time: Frictionless linear guide rails guarantee precise, high-speed, and accurate injection for consistent product quality.

- Effortless Maintenance: Upturning purge safety guard simplifies cleaning, and the easy-slide hopper allows effortless movement for maximized uptime.

- Unparalleled Cooling Efficiency: Specially designed heat exchanger ensures optimal cooling even in extreme temperatures, extending machine life and reducing energy consumption.

- A Symphony of Speed and Control: Servo-hydraulic system delivers precise and high-repeatability cycles with faster moving platens and exceptional control for optimized production output.

- Advanced Mold Protection: Responsive protection features safeguard valuable molds, minimizing the risk of damage and costly repairs.

- Large Tie Bar Distance: Accommodate even the most demanding applications with the Forza Series' generous tie bar distance, ideal for larger hot runner molds.

- Multi-Stage Holding Pressure Control: Enjoy superior defect control with multi-stage pressure management, ensuring consistent and flawless products.

- High-Quality Control Systems: Accurate linear position sensor and user-friendly controller screen provide effortless monitoring and adjustments for optimal production control.

Futech – Your Partner for Peak Performance Molding.

Contact us today and discover how the Forza Series can elevate your production to new heights!