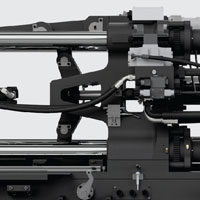

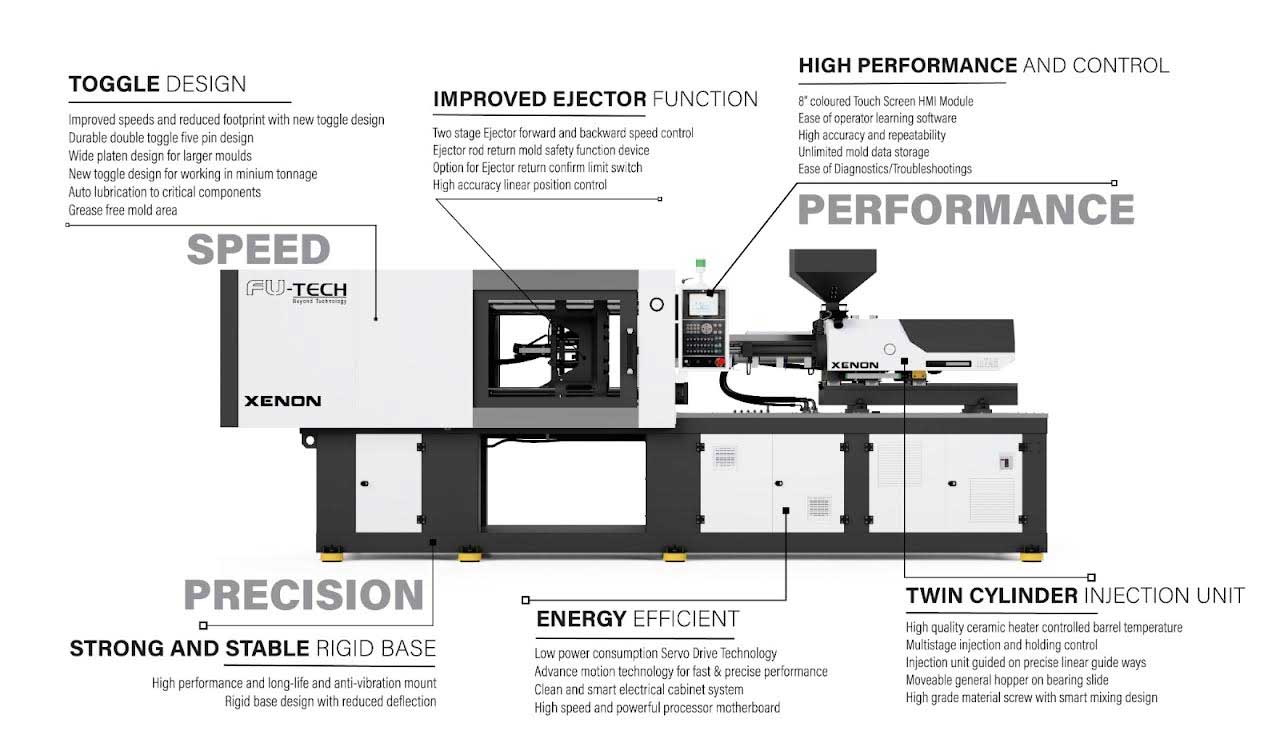

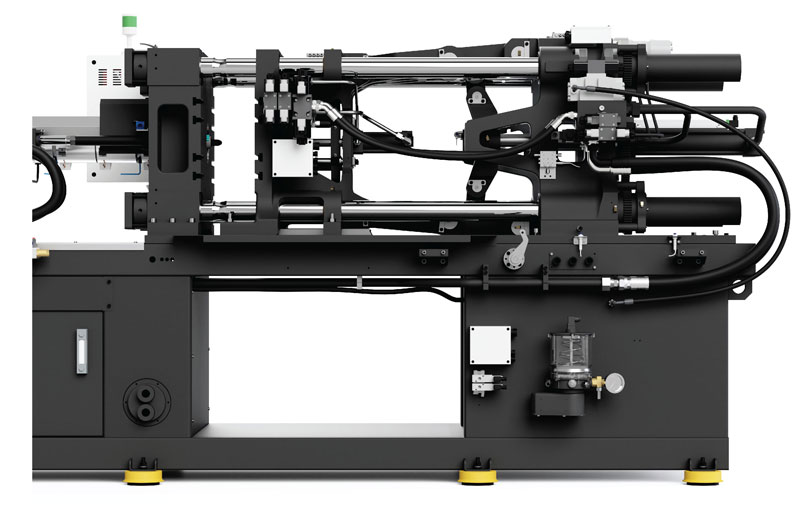

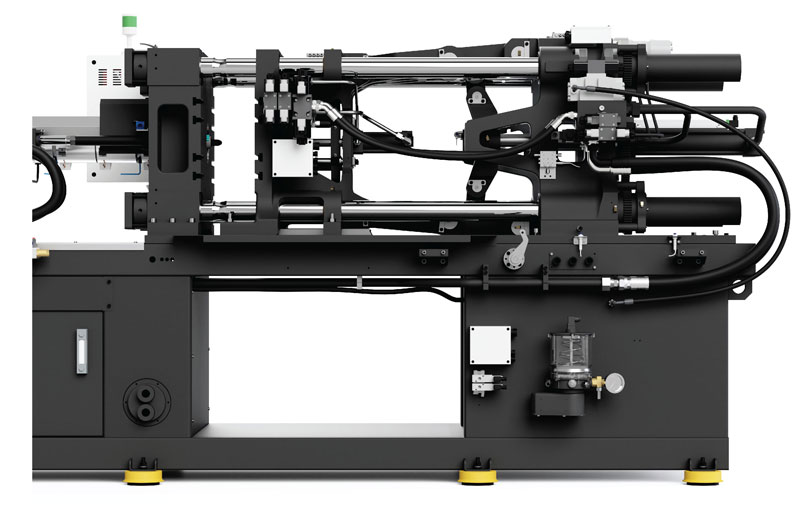

Xenon Series Injection Molding Machine: Compact Powerhouse for High-Speed, Efficient Molding

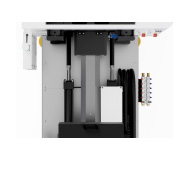

Stop sacrificing efficiency for space! The Xenon Series injection molding machine delivers exceptional performance and lightning-fast production in a compact, space-saving design.

Reduce your energy costs while churning out top-quality parts at rapid speeds. The Xenon Series is an efficiency powerhouse, minimizing downtime with its easy-clean design and quick mold changes. Unwavering repeatability is guaranteed with high-speed clamp control and precision sensors.

Make data-driven decisions with the Xenon Series' detailed production tracking, maximizing your production output. Safety is our priority, featuring robust electrical and hydraulic safety measures. Built for years of reliable operation, the Xenon Series boasts a high-rigidity frame and user-friendly touchscreen control.

Intrigued? Explore the Xenon Series' additional features:

- Energy-efficient hybrid system: Minimizes energy consumption.

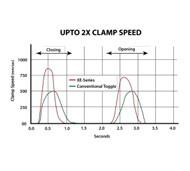

- Exceptional toggle kinematics: Smooth, rapid clamping for faster cycle times.

- Reduced vibrations: Quieter, more stable production environment.

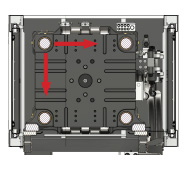

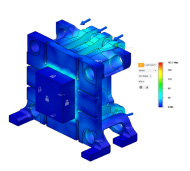

- Smart platen design: Ensures even mold load distribution for consistent quality.

- Multiple configurations: Eight clamp tonnages and six injection unit options.

Don't settle for less. Contact Futech Machinery today and discover how the Xenon Series can transform your production into a high-speed, cost-efficient powerhouse. Get a free quote and see how much you can save!

Overall Features

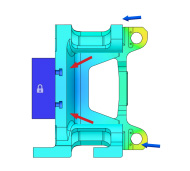

Direct Clamping

- A High-speed energy efficient Servo System combined with a High Efficiency Low Noise Gear pump.

- Smart Toggle Design offers a smooth Clamp Velocity profile with very less Jerk Loads and pressure spikes.

- Strong Frame design to withstand High Momentum loads of high clamp velocity and braking.

- Optimized platen designs for long durability of complete machine mechanically.

- Smart design of Moving platen ensures a uniform load distribution across the mould.

- Advanced Auto-Die Height adjustment feature to ensure operators can set accurate tonnage required for production.

- Accurate Platen parallelism throughout ensures long mould and machine life.

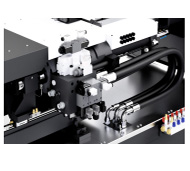

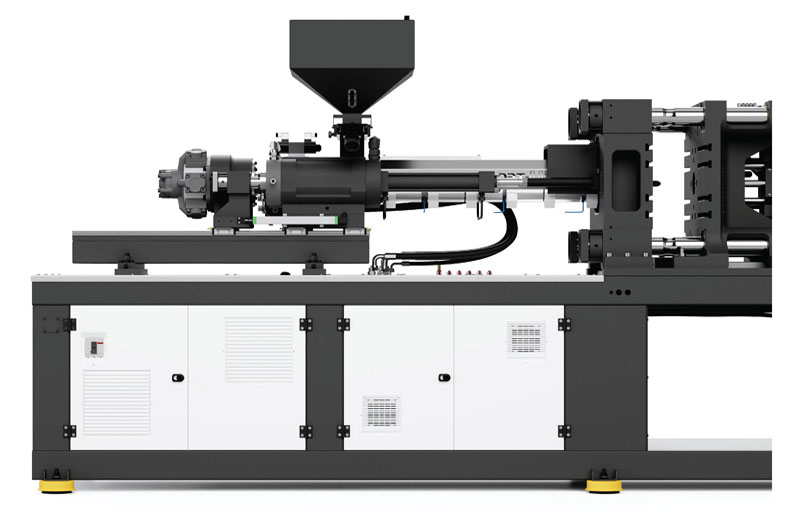

Injection Unit

- High Screw RPM with Better Control offers low Refilling Time.

- Smart Screw Designs for better processing Quality.

- High Repeatable Injection and Refilling Positions for best Consistency of Quality of your Production.

- Redesigned Hydraulics Design for Smart Control of Back Pressure proportionally with best accuracy.

- Modular Selection of Every Injection Unit with 3 Clamp Tonnages.

- Compatible Design for applications where machine used for Faster Cycles.

- Precise High Quality Hydraulic Motor for Consistent Refilling Process.

- Linear Guide Blocks offer Electric saving and offer less Drag in every cycle.

Servo Hydraulic

- Smart Design of Hydraulics offers very short length to complete circuit offers less pressure drop and better electrical efficiency.

- High response Hydraulic Valves prevent harmful pressure spikes and ensure smooth and long life operation.

- Cartridge Control for Refilling ensures smooth screw RPM Control with very less pressure drop.

- High quality durable Hose pipes in hydraulic circuit.

- Rigid Servo Drive and other electronic for Harsh and frequent changing weather and dust conditions.

- Zero welding Point Hydraulic Circuit ensures leakage free operations of machine for years.

- High Grade and quality Hydraulic fittings to ensure seamless hydraulic operations.

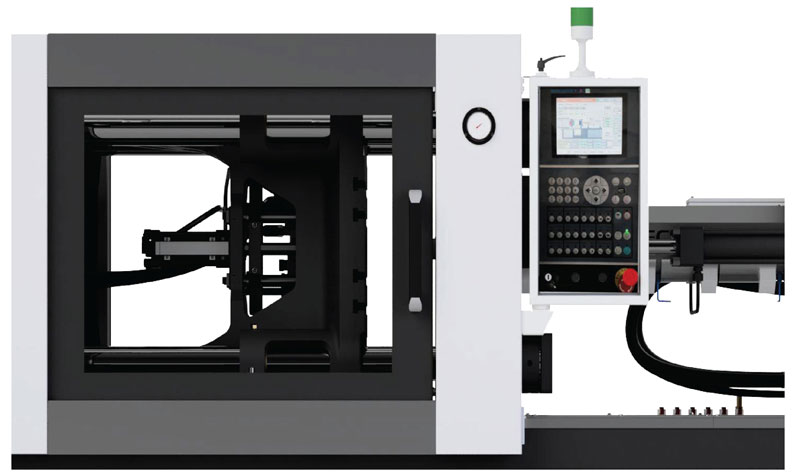

Control Unit

Overview page for access of all controls on single page.

Production data with electrical consumption.

8" Touch screen display high resolution.

Dynamic password data protection levels.

Electrical consumption display on screen.

Theoretical tonnage display on screen.

Graphical analysis of every function.

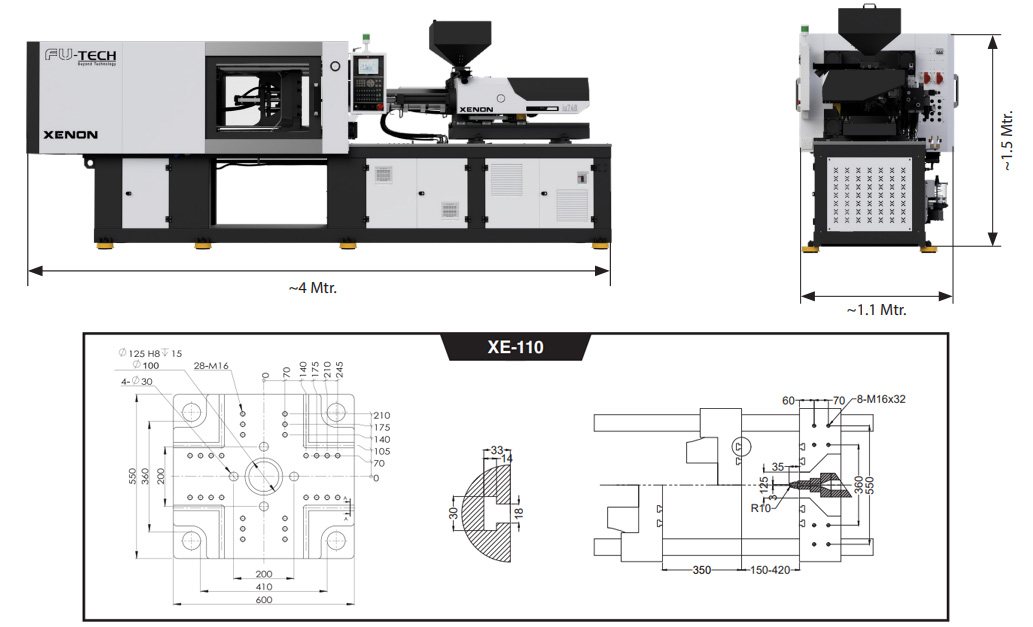

Technical Specifications of XENON Series- 110 Injection Moulding Machine

| Description | Unit | XE-110 | ||||||||

| IU-301 | IU-507 (STD) | IU-622 | ||||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Dia | mm | 30 | 35 | 40 | 35 | 40 | 45 | 38 | 43 | 48 |

| LD Ratio | 25 | 21 | 18 | 24 | 21 | 19 | 23 | 20 | 18 | |

| Injection Stroke | mm | 150 | 200 | 225 | ||||||

| Injection Capacity (GPPS) | gms | 96 | 131 | 172 | 175 | 228 | 289 | 232 | 297 | 370 |

| Injection Capacity | cc | 106 | 144 | 189 | 193 | 251 | 318 | 255 | 326 | 407 |

| Injection Pressure | bar | 2836 | 2083 | 1595 | 2632 | 2015 | 1592 | 2442 | 1907 | 1530 |

| Screw RPM | rpm | 392 | 261 | 261 | ||||||

| Injection Rate | cc/sec | 73 | 100 | 131 | 80 | 103 | 162 | 93 | 119 | 149 |

| Clamping Force | Ton | 110 | 110 | 110 | ||||||

| Tie Bar Distance | mm | 410 X 360 | 410 X 360 | 410 X 360 | ||||||

| Opening Stroke | mm | 350 | 350 | 350 | ||||||

| Min. Mold Height | mm | 150 | 150 | 150 | ||||||

| Max. Mold Height | mm | 420 | 420 | 420 | ||||||

| Max. Daylight | mm | 770 | 770 | 770 | ||||||

| Ejector Stroke | mm | 110 | 110 | 110 | ||||||

| Pump Motor | kW | 12 | 12 | 12 | ||||||

| Ejector Force | kN | 32 | 32 | 32 | ||||||

| Oil Tank Capacity | L | 160 | 160 | 160 | ||||||

| Machine Dimensions (Approx.) | Mtr. | X 1.1 X 1.5 | 4x 1.1 X 1.5 | 4.2x1.1 X | 1.5 | |||||

| Machine Weight (Approx.) | Ton | 3.75 | 3.75 | 3.75 | ||||||

| Heater Load | kW | 8 | 9.5 | 9.5 | ||||||

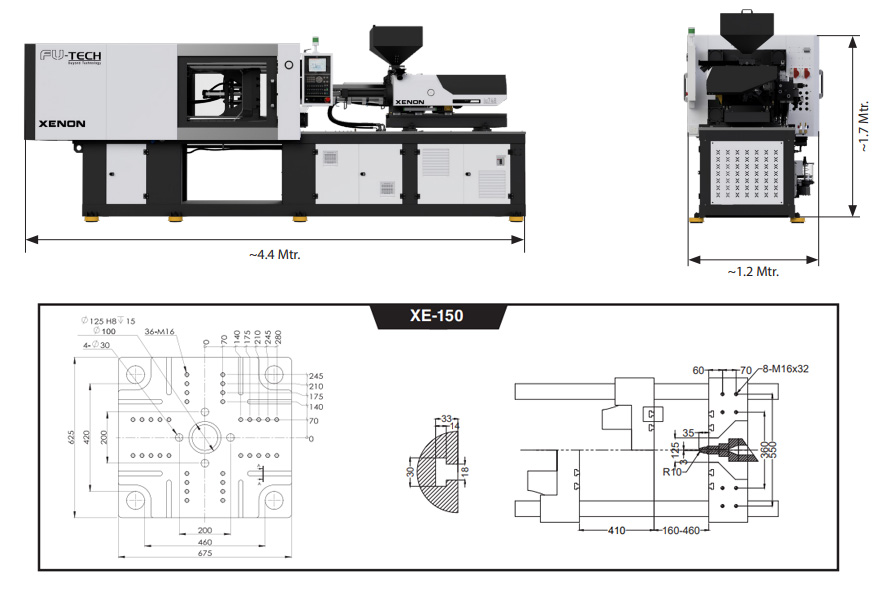

Technical Specifications of XENON Series- 150 Injection Moulding Machine

| Description | Unit | XE-150 | ||||||||

| IU-507 | IU-622 (STD) | IU-748 | ||||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Dia | mm | 35 | 40 | 45 | 38 | 43 | 48 | 40 | 45 | 50 |

| LD Ratio | 24 | 21 | 19 | 23 | 20 | 18 | 26 | 23 | 21 | |

| Injection Stroke | mm | 200 | 225 | 250 | ||||||

| Injection Capacity (GPPS) | gms | 175 | 228 | 289 | 232 | 297 | 370 | 285 | 362 | 447 |

| Injection Capacity | CC | 193 | 251 | 318 | 255 | 326 | 407 | 314 | 398 | 491 |

| Injection Pressure | bar | 2632 | 2015 | 1592 | 2442 | 1907 | 1530 | 2380 | 1880 | 1523 |

| Screw RPM | rpm | 261 | 261 | 280 | ||||||

| Injection Rate | cc/sec | 80 | 103 | 162 | 93 | 119 | 149 | 110 | 139 | 208 |

| Clamping Force | Ton | 150 | 150 | 150 | ||||||

| Tie Bar Distance | mm | 460 X 420 | 460 X 420 | 460 X 420 | ||||||

| Opening Stroke | mm | 410 | 410 | 410 | ||||||

| Min. Mold Height | mm | 160 | 160 | 160 | ||||||

| Max. Mold Height | mm | 460 | 460 | 460 | ||||||

| Max. Daylight | mm | 850 | 850 | 850 | ||||||

| Ejector Stroke | mm | 125 | 125 | 125 | ||||||

| Pump Motor | kW | 12 | 12 | 18.2 | ||||||

| Ejector Force | kN | 50 | 50 | 50 | ||||||

| Oil Tank Capacity | L | 180 | 180 | 180 | ||||||

| Machine Dimensions (Approx.) | Mtr. | 4.4 | X 1.2 X | 1.7 | 4.4 | X 1.2 X | 1.7 | 4.4 | X 1.2 X | 1.7 |

| Machine Weight (Approx.) | Ton | 4.5 | 4.5 | 4.5 | ||||||

| Heater Load | kW | 9.5 | 9.5 | 11 | ||||||

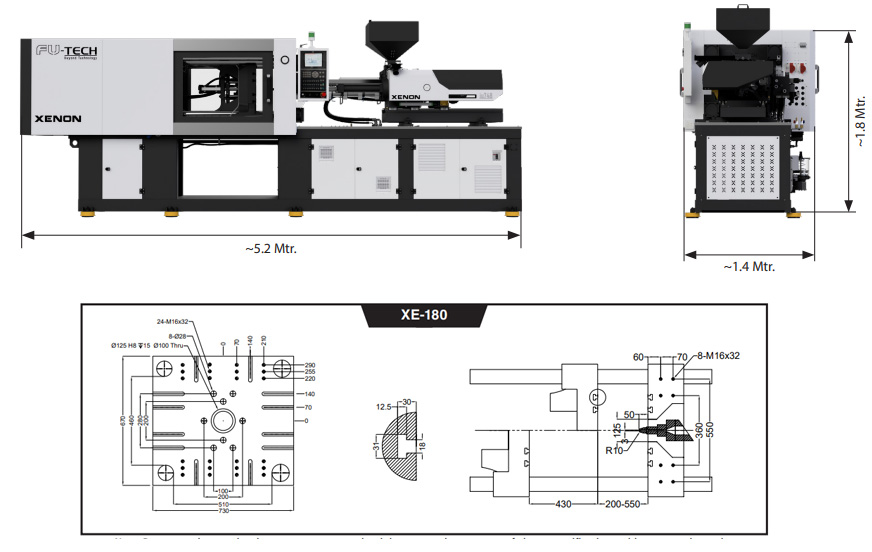

Technical Specifications of XENON Series- 180 Injection Moulding Machine

| Description | Unit | XE-180 | ||||||||

| IU-622 | IU-748 (STD) | IU-996 | ||||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Dia | mm | 38 | 43 | 48 | 40 | 45 | 50 | 45 | 50 | 55 |

| LD Ratio | 23 | 20 | 18 | 26 | 23 | 21 | 26 | 23 | 21 | |

| Injection Stroke | mm | 225 | 250 | 275 | ||||||

| Injection Capacity (GPPS) | gms | 232 | 297 | 370 | 285 | 362 | 447 | 398 | 491 | 595 |

| Injection Capacity | CC | 255 | 326 | 407 | 314 | 398 | 491 | 438 | 540 | 654 |

| Injection Pressure | bar | 2442 | 1907 | 1530 | 2380 | 1880 | 1523 | 2776 | 1843 | 1523 |

| Screw RPM | rpm | 261 | 280 | 250 | ||||||

| Injection Rate | cc/sec | 93 | 119 | 149 | 110 | 139 | 208 | 146 | 180 | 218 |

| Clamping Force | Ton | 180 | 180 | 180 | ||||||

| Tie Bar Distance | mm | 510 X 460 | 510 X 460 | 510 X 460 | ||||||

| Opening Stroke | mm | 430 | 430 | 430 | ||||||

| Min. Mold Height | mm | 200 | 200 | 200 | ||||||

| Max. Mold Height | mm | 550 | 550 | 550 | ||||||

| Max. Daylight | mm | 980 | 980 | 980 | ||||||

| Ejector Stroke | mm | 125 | 125 | 125 | ||||||

| Pump Motor | kW | 18.2 | 18.2 | 28 | ||||||

| Ejector Force | kN | 80 | 80 | 80 | ||||||

| Oil Tank Capacity | L | 200 | 200 | 200 | ||||||

| Machine Dimensions (Approx.) | Mtr. | 5.2x1.4x1.8 | 5.2x1.4x1.8 | 5.2x1.4x1.8 | ||||||

| Machine Weight (Approx.) | Ton | 6 | 6 | 6 | ||||||

| Heater Load | kW | 11 | 11 | 16 | ||||||

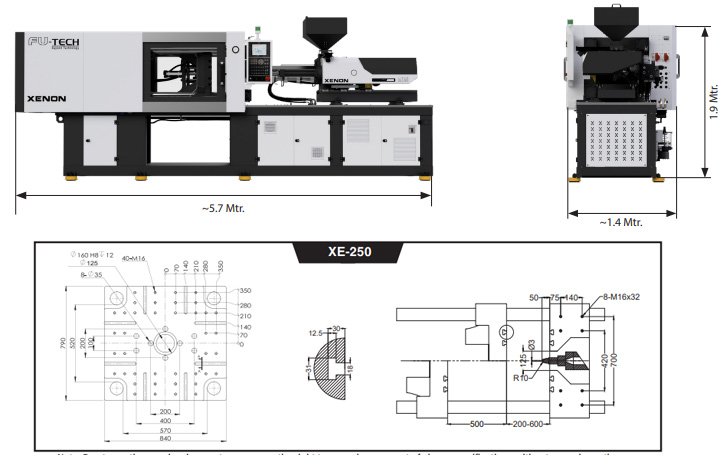

Technical Specifications of XENON Series- 250 Injection Moulding Machine

| Description | Unit | XE-250 | ||||||||

| IU-996 | IU-1426 (STD) | IU-1691 | ||||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Dia | mm | 45 | 50 | 55 | 50 | 55 | 60 | 55 | 60 | 70 |

| LD Ratio | 26 | 23 | 21 | 25 | 23 | 21 | 27 | 22 | 19 | |

| Injection Stroke | mm | 275 | 300 | 325 | ||||||

| Injection Capacity (GPPS) | gms | 398 | 491 | 595 | 535 | 648 | 772 | 702 | 836 | 1175 |

| Injection Capacity | CC | 438 | 540 | 654 | 589 | 713 | 849 | 772 | 919 | 1291 |

| Injection Pressure | bar | 2776 | 1843 | 1523 | 2419 | 1999 | 1680 | 2190 | 1840 | 1352 |

| Screw RPM | rpm | 250 | 220 | 210 | ||||||

| Injection Rate | cc/sec | 146 | 180 | 218 | 170 | 205 | 288 | 204 | 243 | 331 |

| Clamping Force | Ton | 250 | 250 | 250 | ||||||

| Tie Bar Distance | mm | 570 X 520 | 570 X 520 | 570 X 520 | ||||||

| Opening Stroke | mm | 500 | 500 | 500 | ||||||

| Min. Mold Height | mm | 200 | 200 | 200 | ||||||

| Max. Mold Height | mm | 600 | 600 | 600 | ||||||

| Max. Daylight | mm | 1100 | 1100 | 1100 | ||||||

| Ejector Stroke | mm | 150 | 150 | 150 | ||||||

| Pump Motor | kW | 18.2 | 28 | 28 | ||||||

| Ejector Force | kN | 80 | 80 | 80 | ||||||

| Oil Tank Capacity | L | 280 | 280 | 280 | ||||||

| Machine Dimensions (Approx.) | Mtr. | 5.7 | X 1.4 X | 1.9 | 5.7 | X 1.4 X | 1.9 | 5.9 | X 1.4 X | 1.9 |

| Machine Weight (Approx.) | Ton | 9 | 9 | 9 | ||||||

| Heater Load | kW | 16 | 20 | 22.4 | ||||||

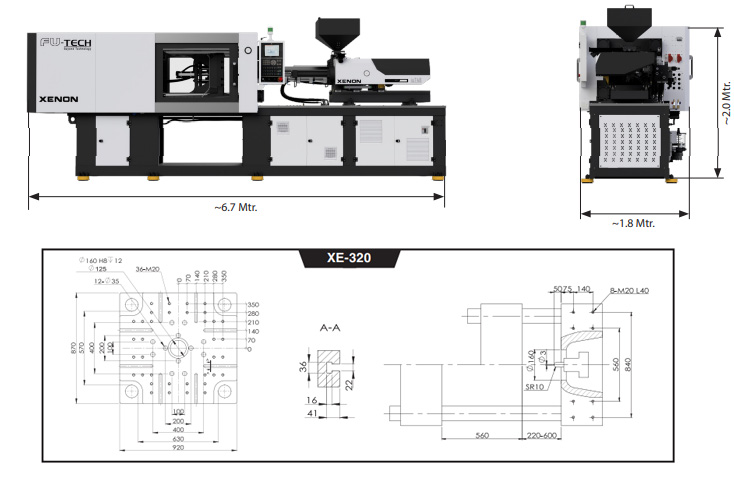

Technical Specifications of XENON Series- 320 Injection Moulding Machine

| Description | Unit | XE-320 | ||||||||

| IU-1426 | IU-1691 (STD) | IU-2614 | ||||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Dia | mm | 50 | 55 | 60 | 55 | 60 | 70 | 60 | 70 | 80 |

| LD Ratio | 25 | 23 | 21 | 27 | 22 | 19 | 24 | 21 | 18 | |

| Injection Stroke | mm | 300 | 325 | 355 | ||||||

| Injection Capacity (GPPS) | gms | 535 | 648 | 772 | 702 | 836 | 1175 | 901 | 1226 | 1601 |

| Injection Capacity | CC | 589 | 713 | 849 | 772 | 919 | 1291 | 990 | 1348 | 1760 |

| Injection Pressure | bar | 2419 | 1999 | 1680 | 2190 | 1840 | 1352 | 2640 | 1940 | 1485 |

| Screw RPM | rpm | 220 | 210 | 187 | ||||||

| Injection Rate | cc/sec | 170 | 205 | 288 | 204 | 243 | 331 | 227 | 309 | 404 |

| Clamping Force | Ton | 320 | 320 | 320 | ||||||

| Tie Bar Distance | mm | 630 X 570 | 630 X 570 | 630 X 570 | ||||||

| Opening Stroke | mm | 580 | 580 | 580 | ||||||

| Min. Mold Height | mm | 230 | 230 | 230 | ||||||

| Max. Mold Height | mm | 630 | 630 | 630 | ||||||

| Max. Daylight | mm | 1230 | 1230 | 1230 | ||||||

| Ejector Stroke | mm | 170 | 170 | 170 | ||||||

| Pump Motor | kW | 28 | 28 | 40.5 | ||||||

| Ejector Force | kN | 110 | 110 | 110 | ||||||

| Oil Tank Capacity | L | 350 | 350 | 350 | ||||||

| Machine Dimensions (Approx.) | Mtr. | 6.7 | X 1.8 X | 2 | 6.7 | X 1.8 X | 2 | 6.7 | X 1.8 X | 2 |

| Machine Weight (Approx.) | Ton | 12.5 | 12.5 | 12.5 | ||||||

| Heater Load | kW | 20 | 22.4 | 27.7 | ||||||

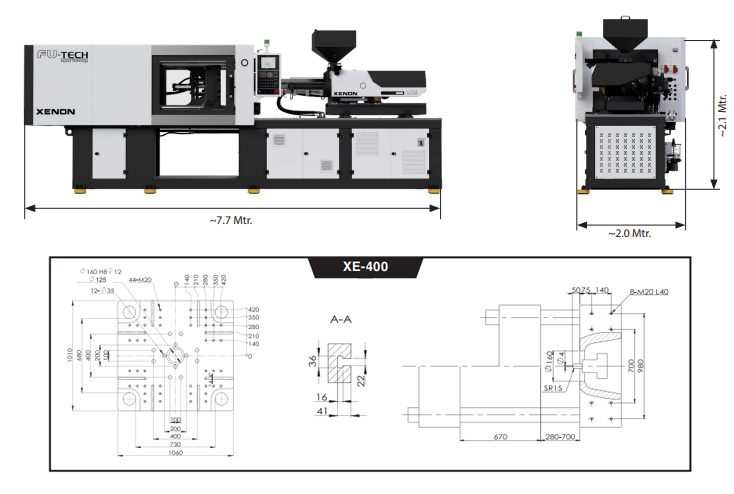

Technical Specifications of XENON Series- 400 Injection Moulding Machine

| Description | Unit | XE-400 | ||||||||

| IU-1691 | IU-2614 (STD) | IU-3394 | ||||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Dia | mm | 55 | 60 | 70 | 60 | 70 | 80 | 70 | 80 | 90 |

| LD Ratio | 27 | 22 | 19 | 24 | 21 | 18 | 24 | 21 | 19 | |

| Injection Stroke | mm | 325 | 355 | 375 | ||||||

| Injection Capacity (GPPS) | gms | 702 | 836 | 1175 | 901 | 1226 | 1601 | 1314 | 1716 | 2172 |

| Injection Capacity | CC | 772 | 919 | 1291 | 990 | 1348 | 1760 | 1444 | 1886 | 2387 |

| Injection Pressure | bar | 2190 | 1840 | 1352 | 2640 | 1940 | 1485 | 2351 | 1800 | 1422 |

| Screw RPM | rpm | 210 | 187 | 192 | ||||||

| Injection Rate | cc/sec | 204 | 243 | 331 | 227 | 309 | 404 | 350 | 457 | 578 |

| Clamping Force | Ton | 400 | 400 | 400 | ||||||

| Tie Bar Distance | mm | 730 X 680 | 730 X 680 | 730 X 680 | ||||||

| Opening Stroke | mm | 670 | 670 | 670 | ||||||

| Min. Mold Height | mm | 280 | 280 | 280 | ||||||

| Max. Mold Height | mm | 700 | 700 | 700 | ||||||

| Max. Daylight | mm | 1370 | 1370 | 1370 | ||||||

| Ejector Stroke | mm | 180 | 180 | 180 | ||||||

| Pump Motor | kW | 28 | 40.5 | 45.2 | ||||||

| Ejector Force | kN | 110 | 110 | 110 | ||||||

| Oil Tank Capacity | L | 430 | 430 | 430 | ||||||

| Machine Dimensions (Approx.) | Mtr. | 7.7 | X 2.0 X | 2.1 | 7.7 | X 2.0 X | 2.1 | 7.7 | X 2.0 X | 2.1 |

| Machine Weight (Approx.) | Ton | 16 | 16 | 16 | ||||||

| Heater Load | kW | 22.4 | 27.7 | 32.15 | ||||||

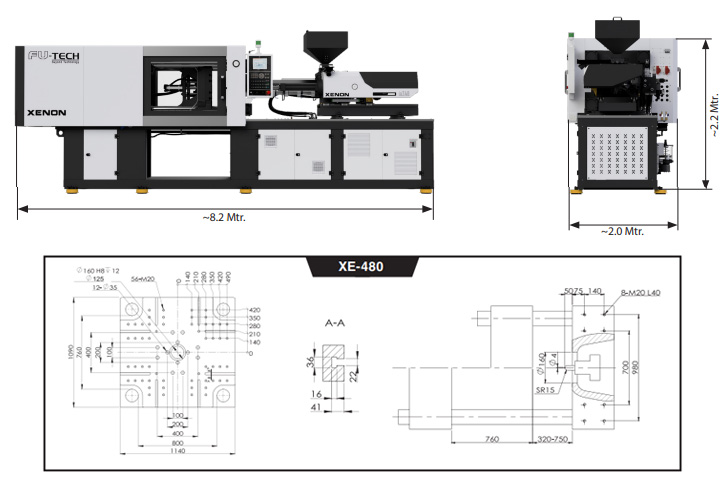

Technical Specifications of XENON Series- 480 Injection Moulding Machine

| Description | Unit | XE - 480 | ||||||||

| IU - 2614 | IU - | 3394 ( STD | ) | IU - 4526 | ||||||

| A | B | C | A | B | C | A | B | C | ||

| Screw Dia | mm | 60 | 70 | 80 | 70 | 80 | 90 | 80 | 90 | 100 |

| LD Ratio | 24 | 21 | 18 | 24 | 21 | 19 | 24 | 21 | 19 | |

| Injection Stroke | mm | 355 | 375 | 420 | ||||||

| Injection Capacity ( GPPS ) | gms | 901 | 1226 | 1601 | 1314 | 1716 | 2172 | 1920 | 2429 | 3000 |

| Injection Capacity | CC | 990 | 1348 | 1760 | 1444 | 1886 | 2387 | 2110 | 2670 | 3297 |

| Injection Pressure | bar | 2640 | 1940 | 1485 | 2351 | 1800 | 1422 | 2145 | 1694 | 1372 |

| Screw RPM | rpm | 187 | 192 | 150 | ||||||

| Injection Rate | cc / sec | 227 | 309 | 404 | 350 | 457 | 578 | 373 | 472 | 588 |

| Clamping Force | Ton | 480 | 480 | 480 | ||||||

| Tie Bar Distance | mm | 800 x 760 | 800 x 760 | 800 x 760 | ||||||

| Opening Stroke | mm | 780 | 780 | 780 | ||||||

| Min . Mold Height | mm | 320 | 320 | 320 | ||||||

| Max . Mold Height | mm | 750 | 750 | 750 | ||||||

| Max . Daylight | mm | 1530 | 1530 | 1530 | ||||||

| Ejector Stroke | mm | 200 | 200 | 200 | ||||||

| Pump Motor | kW | 40.5 | 45.2 | 65 | ||||||

| Ejector Force | kN | 110 | 110 | 110 | ||||||

| Oil Tank Capacity | L | 550 | 550 | 550 | ||||||

| Machine Dimensions ( Approx . ) | Mtr . | 8.2 | x 2.0 x | 2.2 | 8.2 | x 2.0 x | 2.2 | 8.2 | x 2.0 x | 2.2 |

| Machine Weight ( Approx . ) | Ton | 18 | 18 | 18 | ||||||

| Heater Load | kW | 27.7 | 32.15 | 36 |

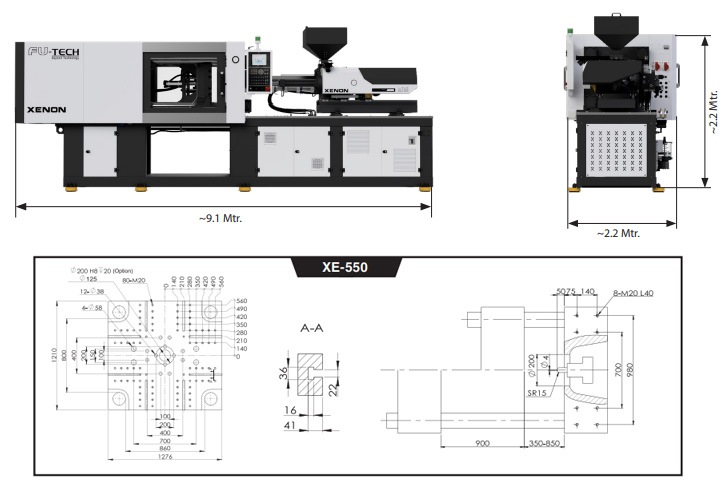

Technical Specifications of XENON Series- 550 Injection Moulding Machine

| Description | Unit | XE | -550 | ||||

| IU - 3394 | IU | - 4526 ( STD | ) | ||||

| A | B | C | A | B | C | ||

| Screw Dia | mm | 70 | 80 | 90 | 80 | 90 | 100 |

| LD Ratio | 24 | 21 | 19 | 24 | 21 | 19 | |

| Injection Stroke | mm | 375 | 420 | ||||

| Injection Capacity ( GPPS ) | gms | 1314 | 1716 | 2172 | 1920 | 2429 | 3000 |

| Injection Capacity | CC | 1444 | 1886 | 2387 | 2110 | 2670 | 3297 |

| Injection Pressure | bar | 2351 | 1800 | 1422 | 2145 | 1694 | 1372 |

| Screw RPM | rpm | 192 | 150 | ||||

| Injection Rate | cc / sec | 350 | 457 | 578 | 373 | 472 | 588 |

| Clamping Force | Ton | 550 | 550 | ||||

| Tie Bar Distance | mm | 860 x 800 | 860 x 800 | ||||

| Opening Stroke | mm | 900 | 900 | ||||

| Min . Mold Height | mm | 350 | 350 | ||||

| Max . Mold Height | mm | 850 | 850 | ||||

| Max . Daylight | mm | 1750 | 1750 | ||||

| Ejector Stroke | mm | 250 | 250 | ||||

| Pump Motor | kW | 45.2 | 65 | ||||

| Ejector Force | KN | 130 | 130 | ||||

| Oil Tank Capacity | L | 650 | 650 | ||||

| Machine Dimensions ( Approx . ) | Mtr . | 9.1 | x 2.2 x 2.2 | 9.1 x 2.2 x 2.2 | |||

| Machine Weight ( Approx . ) | Ton | 20 | 20 | ||||

| Heater Load | kW | 32.15 | 36 | ||||

Features of XENON Series Injection Moulding Machine

| CLAMPING UNIT |

| 5 stage adjustable opening and closing speeds |

| Automatic Die Height Adjustment Feature |

| Clamp Force Decompression during Cooling. |

| Progressive Automatic Grease Lubrication |

| Grease Tray added below Toggle Points for better Maintenance |

| Robot Mounting on Fix Platen. |

| T-Slot Platens |

| Adjustable Bronze Pad Shoe for Moving Platen. |

| 42CrMoAl Made Tie Bars |

| Precise Transducer for Clamp Stroke Control |

| Low Pressure Mold Protection |

| Automatic Centralized Lubrication System |

| Auto Lubrication |

| 2-Stage Ejector Forward Backward Control |

| Strong Hydraulic and Electrical Gate Safety Devices |

| High Quality Phosphorous Bronze Tie-bar Bushings |

| Extended Day Light |

| Dual Air Ejection |

| Filter, Regulator and Lubricator (FRL) Unit for air blow |

| Dual Core Pulling |

| Open loop Proportional Clamp Stroke Control |

| Closed Loop proportional Clamp Stroke Control |

| HYDRAULIC SYSTEMS |

| High Performance Hydraulic Valves |

| High Quality Durable Oil Sealing Design |

| Low Noise Hydraulic Design |

| Efficient Hydraulic Oil Cooling Device |

| Oil Level and Temperature Alarm |

| Low Pressure Drop and High Efficiency Hydraulic Design |

| High Quality and rating Hose Pipes |

| High Quality Coating on Hydraulic Manifolds |

| Welding Less Hydraulic System |

| Embedded Hydraulic Piping Inside Machine Base |

| Hydraulic Gate Safety Device |

| OTHER FEATURES |

| Stainless Steel Base Covers |

| Stainless Steel Chain Guard Operator Side |

| Taper Tray for Part Drop |

| Leveling Pads. |

| Tool Kit |

| General Hopper |

| In-Built Toolbox |

| 16Amp Power Socket |

| Top Cover with Electrical Safety Device |

| INJECTION UNIT |

| Twin Cylinder Injection Unit |

| Standard Barrier Flight Nitride Screw |

| Proportional Back Pressure Control |

| Standard B-Screw |

| Time and Position Based switchover for Holding. |

| injection Purge Guard Safety Device |

| insulated Ceramic Heaters |

| Sliding Hopper with Lid and Autoloader Mounting. |

| injection Unit on Linear Guide Rails |

| Dual Carriage Cylinders |

| Bi-Metallic Ring Cone Plunger Set |

| Automatic Purging Feature |

| Screw Cold Start Protection |

| Precise injection Position Transducer |

| Actual Screw RPM Display. |

| Stainless Steel Barrel & Heater Cover |

| Non-Standard Screw |

| Bi-Metallic Screw & Barrel |

| Hopper Dryer |

| Auto Loading Unit. |

| Proportional Injection Speed Control |

| Proportional Screw RPM Control |

| Chrome Plated Screw |

| Shut-off Nozzle |

| Nanotech Infrared Heaters for Electrical Saving |

| Extended Nozzle with Heater |

| Hopper Magnet |

| CONTROL SYSTEMS |

| 8" Touch Screen Display High Resolution |

| Advanced High-Speed Controller |

| Actual Injection Speed Display |

| Unlimited Mould Storage |

| Overview Page for Access of all Controls on Single Page |

| Dynamic Password Data Protection Levels |

| Production Data with Electrical Consumption |

| Electrical Consumption display on screen |

| Graphical Analysis of every Function |

| Emergency Stop Button |

| Theoretical Tonnage Display on Screen |

| Short Circuit Proof High Rating SSR |

| SPC Data Monitoring |

| Euro MAP 12 Robot Interface |

| Network Management System |

| 10" Touchscreen Display |

Shot Weight Conversion

| MATERIAL | FACTOR |

| PC / CAB | 0.97 |

| PE | 0.71 |

| PMMA / PC + ABS | 0.94 |

| POM | 1.15 |

| PET / PBT | 1.08 |

| CA / PVC Rigid | 1.02 |

| PVC Flexible | 1.12 |

| PF (Thermoset) | 1.3 |

| UP (Thermoset) | 1.6 |

| MATERIAL | FACTOR |

| HD-PE | 0.75 |

| LD-PE / PP | 0.73 |

| PP + 20% Talcum | 0.85 |

| PP + 40% Talcum | 0.98 |

| PP + 20% GF | 0.85 |

| PS | 0.91 |

| ABS / SB / SAN | 0.88 |

| PA | 1.91 |

| PA6 + 30% GF | 1.14 |

Why Choose Futech and the Xenon Series?

- Space-Saving Powerhouse: Achieve peak performance in a compact design. The Xenon Series maximizes efficiency and minimizes energy consumption.

- Unwavering Repeatability: High-speed clamp control and precision sensors ensure consistent, error-free production runs.

- Data-Driven Decisions: Track production data and optimize operations for maximum efficiency.

- Safety First: Robust safety features prioritize operator well-being.

- Built to Last: High-rigidity construction ensures long-lasting performance and minimal downtime.

- Effortless Control: User-friendly touchscreen interface simplifies operation and reduces training time.

- Unparalleled Efficiency, Exceptional Value: Delivers top results while minimizing energy consumption, maximizing your profit potential.

Choose Futech – Your Trusted Partner in Molding Success.

Contact us today to explore how the Xenon Series can revolutionize your production!