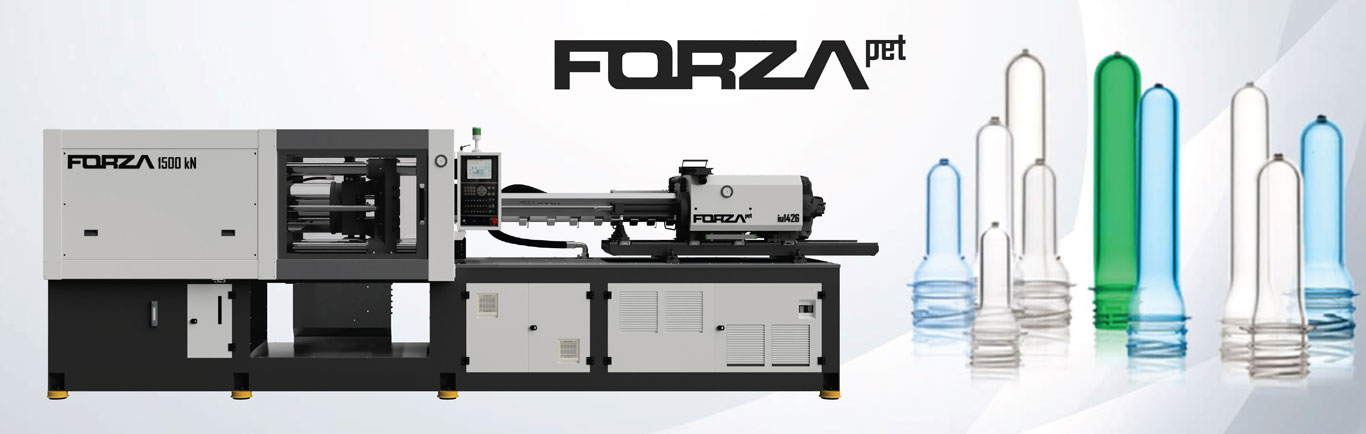

Unleash High-Speed PET Preform Production with the Futech Forza PET Series

In today's competitive beverage industry, efficiency is king. The demand for high-quality PET bottles is ever-growing, and staying ahead requires a production solution that delivers both speed and cost-effectiveness. Introducing the Futech Forza PET Series – a revolutionary injection molding machine specifically designed for high-speed PET preform production.

Engineered with cutting-edge technology and a deep understanding of the PET preform industry, the Forza PET Series empowers you to:

- Achieve unparalleled production speeds: Experience faster cycle times with features like a multi-point ejector system, large mold space, and a high L/D ratio for efficient plasticization.

- Minimize your operating costs: The Forza PET Series' energy-efficient design and space-saving setup translate to lower energy consumption and a more streamlined production floor.

- Maintain exceptional quality control: High-precision injection and clamping units ensure consistent, flawless preforms every single time. This reduces waste and ensures your bottles meet the highest quality standards.

- Maximize uptime and minimize maintenance: The Forza PET Series boasts a robust design with features like direct locking, high moving speeds, and a no-maintenance clamping unit. This translates to less downtime for maintenance and repairs.

- The Power of Servo-Hydraulic Technology: Experience a new level of control. The Forza Series integrates a cutting-edge servo-hydraulic system, delivering a precise and high-repeatability cycle. Faster moving platen movements with exceptional control of speed and pressure optimize your production output, maximizing efficiency.

The Forza PET Series is more than just a machine; it's a complete solution. From the initial consultation to after-sales support, Futech is dedicated to your success. Contact us today and discover how the Forza PET Series can transform your PET preform production into a high-speed, cost-effective powerhouse.

Ready to Provide more Flexibility and Complete Solution

- Automation Complete Range of Automation Solutions which includes Robots and Conveyors. This offers a customised material handling process that could prevent the surface damages caused due to poor material handling process.

- Mould space dehumidifier De-Humidifies the Air surrounding Mould Punch and Cavity which will allow you to run the mould chiller below 5degC, Hence Saving your Cycle time drastically and increasing the production output by a considerable amount

- Dehumidified Air Dryer Dehumidified Air Dryer is used to Remove Moisture from the Plastic Granules. In Comparison to Regular Hot-Air Dryers, Dehumidifier provides much better Pre-form Quality in terms of both Visual and Strength aspects. Also it’s Heat Regeneration features Saves a Considerable amount of electricity used for drying the material

- Auto Loader Three Phase Vacuum Auto Loader ensures that the material is loaded according to it’s dehumidifying time to ensure a non stop production.

- Blending Unit Our Doser and Blending unit ensures very precise dosing of any masterbatch or additive. It’s Stepper motor offers minimum 1.8deg of Rotation with RPM Controlled as low as 0.5 RPM to 200RPM.

- Mezanine Fu-Tech’s Specially designed mezanine is a major space saver. We make sure that thecomplete setup fits in least space without compromising accessibility of the components.

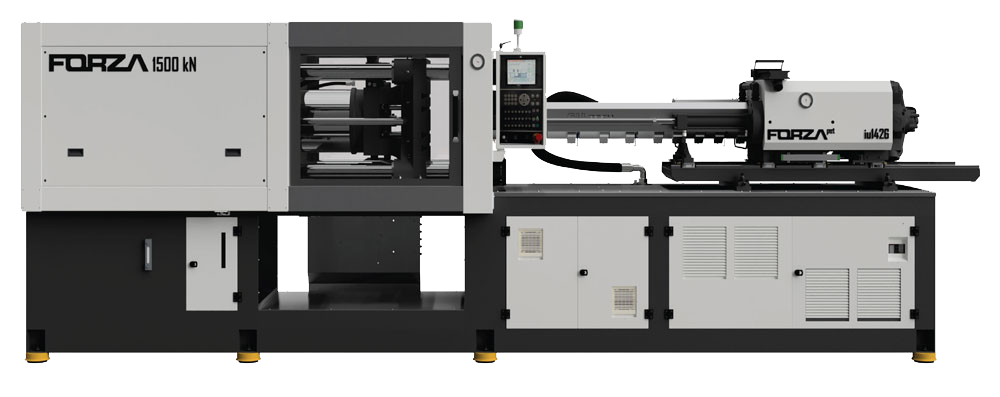

Clamping Unit:

Direct Locking

Perfect Parallelism

High moving speeds

Offers lower cycle time

No maintenance

Bigger Tiep bar Distance

Longer Mold life

Better Mold safety

Injection Unit:

High Speed Plasticizing

High injection rates

Large shot weight capacities

Large L/D ratio of 25

Better shot weight control

Better temperature control

Offers lowest cycle time

Large sizes of hydraulic motor

Technical Specifications of FORZA PET Series Injection Moulding Machine

| Description | Unit | FZ-125/iu507 | FZ-125/iu748 | FZ-150/iu996 | FZ-190/iu1426 | FZ-280/iu1691 | FZ-280/iu2614 |

| Clamping Force | kN | 1250 | 1250 | 1500 | 1900 | 2800 | 2800 |

| Opening Stroke | mm | 600 | 600 | 695 | 695 | 900 | 900 |

| Tie Bar Distance (HxV) | mm | 460x420 | 460x420 | 525x455 | 525/455 | 660X580 | 660X580 |

| Min. Mould Height | mm | 300 | 300 | 290 | 290 | 450 | 450 |

| Total Day Light | mm | 900 | 900 | 985 | 985 | 1350 | 1350 |

| Ejector Stroke | mm | 125 | 125 | 125 | 125 | 180 | 180 |

| Ejector Force | kN | 50 | 50 | 62 | 62 | 80 | 80 |

| Pump/Motor Power | kW | 28.3 | 36.7 | 45.2 | 45.2 | 56.6 | 73.4 |

| Oil Tank Capacity | L | 350 | 350 | 560 | 560 | 840 | 840 |

| Screw Diameter | mm | 50 | 55 | 60 | 70 | 80 | 90 |

| L/D Ratio | 25 | 25 | 25 | 25 | 25 | 25 | |

| Screw Stroke | mm | 200 | 250 | 275 | 300 | 325 | 355 |

| Screw Speed | rpm | 333 | 285 | 280 | 225 | 215 | 222 |

| Shot Weight (PET) | grams | 463 | 700 | 917 | 1361 | 1926 | 2663 |

| Injection Pressure | bar | 1290 | 1258 | 1280 | 1235 | 1035 | 1173 |

| Injection rate | cc/sec | 318 | 330 | 416 | 464 | 773 | 910 |

| Nozzle Force | kN | 67 | 67 | 67 | 83 | 83 | 83 |

| Nozzle Stroke | mm | 250 | 250 | 300 | 300 | 350 | 350 |

| Nozzle Penetration | mm | 50 | 50 | 50 | 50 | 50 | 50 |

| Heating Load | kW | 17 | 20 | 22 | 26 | 32 | 38 |

Why Choose Ftech Machinery's Forza PET Series?

In the fast-paced world of PET preform production, every advantage counts. Here's why the Ftech Forza PET Series is the perfect partner for your success:

- Unmatched Speed and Efficiency: Outpace the competition with the Forza PET Series' high-speed capabilities. Features like a multi-point ejector system, large mold space, and optimized L/D ratio ensure faster cycle times and maximize your production output.

- Cost-Effectiveness at its Finest: Reduce your operating expenses with the Forza PET Series' energy-efficient design. This innovative machine minimizes energy consumption while maintaining exceptional performance, keeping your bottom line healthy.

- Unwavering Quality Control: Confidence in your product starts with confidence in your machine. The Forza PET Series' high-precision injection and clamping units deliver consistent, flawless preforms every single cycle. This translates to minimal waste and PET bottles that meet the most stringent quality standards.

- Minimal Downtime, Maximum Uptime: Don't let maintenance slow you down. The Forza PET Series is built for reliability. Direct locking, high moving speeds, and a no-maintenance clamping unit all contribute to a machine that requires minimal downtime for repairs and maintenance, maximizing your production uptime.

- Space-Saving Design: Optimize your valuable production floor space. The Forza PET Series' compact design provides exceptional performance in a space-efficient footprint. This allows you to maximize your production capacity without sacrificing valuable floor space.

- Complete Turnkey Solution: Ftech is with you every step of the way. From initial consultation and expert advice to after-sales support, we're dedicated to your success. The Forza PET Series is more than just a machine; it's a comprehensive solution that ensures you have the resources and support to achieve peak production efficiency.

- Proven Technology & Expertise: Experience the Ftech difference. With over 20 years of experience and a commitment to cutting-edge technology, Ftech has established itself as a leader in the PET preform molding industry. Choose the Forza PET Series and benefit from a legacy of innovation and reliability.

The Forza PET Series is not just another injection molding machine; it's a high-speed, cost-effective game-changer for PET preform production. Contact Ftech Machinery today and discover how the Forza PET Series can propel your business to new heights of success!